close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

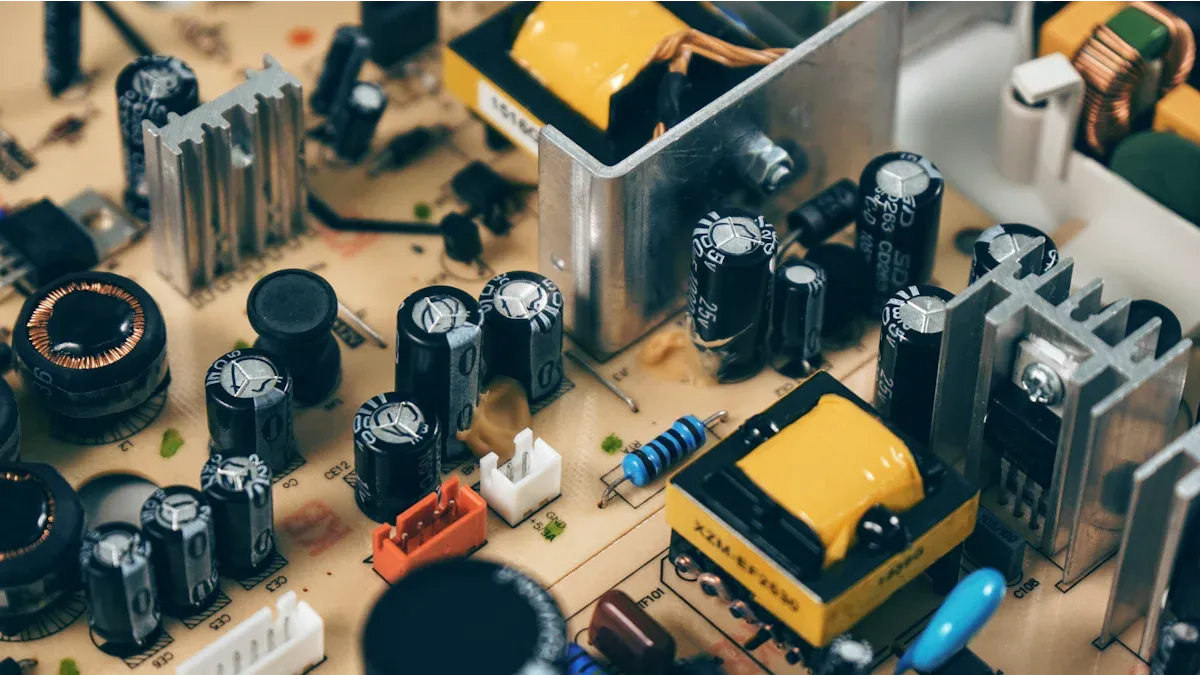

Aluminum Foil laminated CPE is great for electronics packaging. This material stops moisture, oxygen, and light. It keeps sensitive parts safe from damage. The mix of aluminum foil and CPE makes a strong shield. Manufacturers use this because it protects well. Consumers get devices that last longer and work better.

Aluminum Foil laminated CPE uses two strong layers for protection. There is a thin sheet of aluminum foil joined to a layer of chlorinated polyethylene (CPE). The aluminum foil stops water, air, and light from getting in. CPE makes the material bendy and tough. These layers work together to keep electronic parts safe from harm.

Manufacturers like this structure because it is strong and flexible. The aluminum foil keeps out water and oxygen. CPE does not tear or stretch easily. This mix helps protect electronics when they are shipped or stored.

Note: The layers in aluminum foil laminated CPE let it wrap tightly around many products. This helps save space and makes packaging better.

Aluminum Foil laminated CPE has many great features. These make it a good pick for electronics packaging:

Superior Barrier Properties: The aluminum foil layer keeps out water, air, and light. This helps keep electronic parts dry and safe.

High Flexibility: The CPE layer bends without breaking. Packaging fits closely around items and helps stop damage.

Strong Durability: The material does not tear or get holes easily. It keeps electronics safe from rough handling and sharp things.

Chemical Resistance: CPE protects against oils, acids, and other chemicals. This helps stop rust and makes electronics last longer.

| Feature | Benefit for Electronics Packaging |

|---|---|

| Barrier Properties | Keeps out water, air, and light |

| Flexibility | Fits many shapes and sizes |

| Durability | Stops tears and holes |

| Chemical Resistance | Protects from harmful chemicals |

Aluminum Foil laminated CPE helps both manufacturers and buyers. It makes sure electronics arrive safely and last a long time.

Moisture can hurt electronic parts. Water vapor might cause rust or short circuits. Sometimes, it can even break the device. Aluminum Foil laminated CPE stops moisture from getting in. The aluminum foil layer works like a shield. The CPE layer makes the barrier strong and bendy.

Lab tests show this material protects well from moisture. Scientists used a MOCON tester and ASTM E 96 rules. They checked how much water vapor could pass through the Aluminum Foil laminated CPE. The test showed a WVTR of just 0.01 g/m²/24hr. This low number means almost no water vapor gets inside.

| Test Parameter | Result (Aluminum Foil Laminate) | Industry Standard |

|---|---|---|

| WVTR | 0.01 g/m²/24hr | Excellent |

| OTR | 0.01 cc/m²/24hr | Excellent |

Note: Low WVTR numbers help keep electronics dry, even when it is humid.

Oxygen can damage electronics. It can cause rust or other bad reactions. This makes products not last as long. Aluminum Foil laminated CPE keeps air out. The aluminum foil layer blocks oxygen and gases. The CPE layer keeps the seal tight, even if the package bends.

The same lab tests checked how much oxygen could get in. The OTR was 0.01 cc/m²/24hr. This means almost no oxygen enters the package. Electronics stay safe from air damage during shipping and storage.

Electronics are safe from rust and oxidation.

Sensitive parts keep working well for longer.

Light, especially UV rays, can harm electronics. UV can make plastics weak or displays fade. It can also break tiny circuits. Aluminum Foil laminated CPE blocks light and UV rays. The aluminum foil layer reflects both kinds of light. The CPE layer gives extra help.

Manufacturers use this material to stop light from reaching parts. Devices stay safe from sunlight and indoor lights during shipping and storage. This helps electronics last longer and work better.

Tip: Packaging that blocks light and UV rays helps electronics look and work their best.

Electronic devices can get hurt by electromagnetic interference, or EMI. EMI comes from things like other machines, power lines, or wireless signals. These signals can mess up how electronics work. Aluminum foil laminated CPE gives strong protection from these problems.

The aluminum foil layer acts like a wall. It bounces back and soaks up electromagnetic waves. This keeps important circuits safe from outside noise. In lab tests, aluminum foil laminated CPE blocks over 60 dB of electromagnetic waves between 30 MHz and 1 GHz. This high blocking power comes from the aluminum foil’s skill at stopping both EMI and radio frequency interference, or RFI. Many companies use this material in ESD shielding antistatic bags for this reason.

Note: If shielding is above 60 dB, the material blocks more than 99.9% of electromagnetic energy. This much protection helps electronics work right and not break.

The layers also make the material strong. The CPE layer helps the aluminum foil stay tough and bendy. This mix makes sure devices stay safe when shipped, stored, or used every day.

Static electricity can break electronic parts very fast. Even a tiny static shock can ruin microchips or memory cards. Aluminum foil laminated CPE helps stop this damage by moving static charges away quickly.

The metal layer has a resistance lower than 100 ohms per square. This low resistance lets static electricity flow out safely. The surface resistivity is between 10^8 and 10^11 ohms per square, which helps control static. In tests, static goes away in less than 0.02 seconds using FTMS 101 B Method 4046. This quick time means static charges do not build up.

| Property | Measurement / Result | Test Standard / Method |

|---|---|---|

| Metal layer resistance | Less than 100 ohm/sq | Not specified |

| Surface resistivity | 10^8 – 10^11 ohm/sq | Not specified |

| Static removal time | Less than 0.02 seconds | FTMS 101 B Method 4046 |

| Puncture resistance | Greater than 12 lbs (50 N) | ASTM D3420 |

| Moisture vapor transmission rate (MVTR) | Less than 0.3 gm/100in²/24hrs | ASTM E 96 |

| Seal strength | At least 12 lbs/inch (N/15mm) | ASTM D-882-91 |

Tip: Fast static removal and good conductivity help keep electronics safe from static shocks.

Aluminum foil laminated CPE also does not tear easily and keeps water out. These things give extra safety for electronics. Companies trust this material to keep products safe from both EMI and static. Buyers get devices that work well and last a long time.

Aluminum foil laminated CPE is very good at stopping sharp things. The mix of aluminum foil and CPE makes a strong wall. This wall keeps electronic parts safe from pokes and bumps. Packages can get dropped or hit during shipping and storage. This material takes the hit and stops holes or rips. The aluminum foil layer is hard and blocks sharp things. The CPE layer is bendy and adds extra strength. Both layers work together to keep the package safe, even in tough times.

Manufacturers use this material to help stop damage. Devices get to customers in great shape. This makes people trust the brand and helps avoid returns or fixes.

Tip: Picking packaging with strong puncture resistance keeps electronics safe as they travel.

Aluminum foil laminated CPE keeps out chemicals and oils. This is important for electronics in rough places or if spills happen. The material blocks water, air, and other gases. The aluminum foil does not react with oils or chemicals, so the package stays strong.

The layers mix the blocking power of aluminum foil with the flexible, safe CPE film.

Metallized CPE film makes it even better at stopping chemicals and oils, and keeps it strong.

The material meets rules for chemical safety, food safety, and strength.

Careful making and pure materials mean the package does not break down or react with oils or chemicals.

This protection keeps electronics safe from rust, corrosion, or dirt. Makers can use this packaging for products that need extra care.

Flexibility is another big plus for aluminum foil laminated CPE. The CPE layer lets the material bend and stretch without breaking. Packaging can wrap tightly around many shapes and sizes. This saves space and means less extra packing is needed.

Flexible packaging helps workers pack things faster. They can wrap or seal items quickly, which speeds up work. The soft material fits closely, so things do not move inside the package. Electronics stay safe from bumps and shakes.

| Property | Benefit for Electronics |

|---|---|

| Puncture Resistance | Prevents tears and holes |

| Chemical Resistance | Blocks oils and harsh chemicals |

| Flexibility | Fits many shapes and sizes |

Aluminum foil laminated CPE gives strength, safety, and flexibility. Both makers and buyers get electronics that last longer and stay safe.

Aluminum foil laminated CPE gives great thermal insulation. It helps keep electronics safe from quick temperature changes. The aluminum foil layer bounces heat away. The CPE layer slows down how fast heat moves. These two layers work together to keep the inside temperature steady.

Electronics can break if they get too hot or cold. Heat can make circuits stop working. Cold can make parts crack or get wet inside. Aluminum foil laminated CPE helps stop these problems. It keeps the inside near room temperature, even if it is hot or cold outside.

Note: Keeping temperatures steady helps electronics last longer and work well.

Manufacturers like this material because it works well every time. They use it to send products far away. The packaging keeps devices safe from heat in summer and cold in winter. This lowers the chance of returns or repairs.

Here is a simple table to compare materials:

| Material Type | Thermal Insulation | Temperature Range (°F) |

|---|---|---|

| Aluminum Foil Laminated CPE | Excellent | -40 to 158 |

| Standard Plastic Film | Poor | 32 to 122 |

| Paper Packaging | Very Poor | 41 to 104 |

Aluminum foil laminated CPE is better because it works in more temperatures and insulates well.

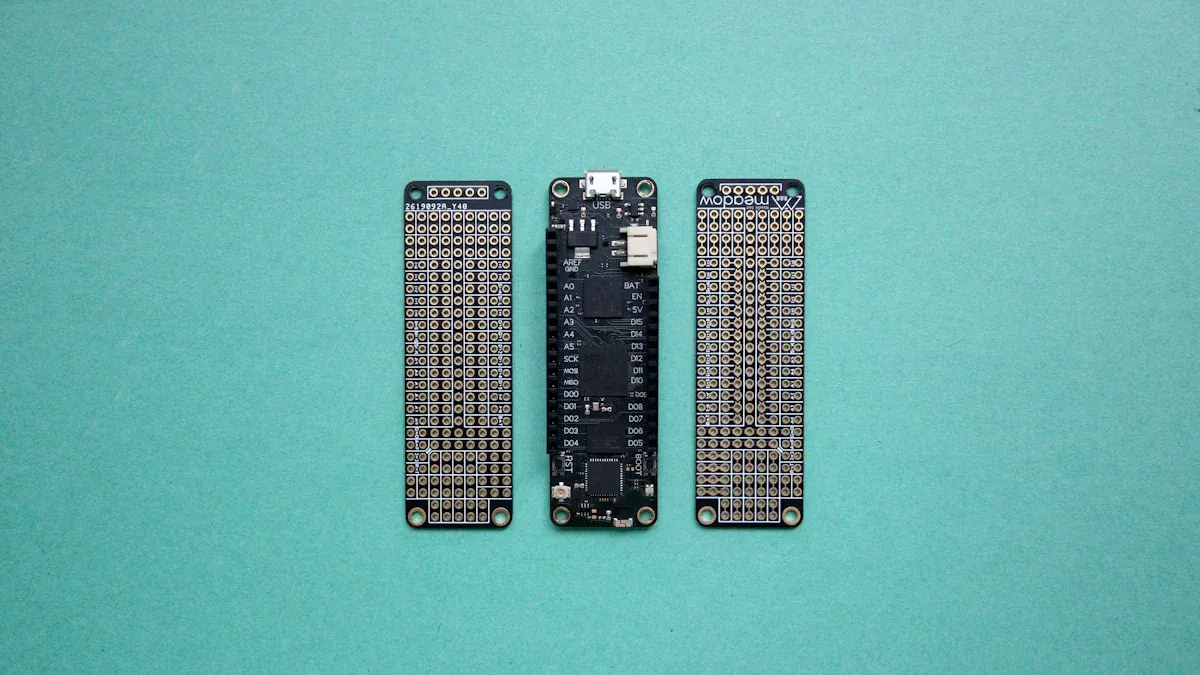

Sensitive electronics need special care. Things like microchips, sensors, and batteries can break from heat or cold. Aluminum foil laminated CPE helps keep these parts safe when shipped or stored.

Many companies use this material for:

Computer parts like CPUs and memory chips

Medical devices with tiny sensors

Industrial control boards

Rechargeable batteries

The packaging wraps tightly around each item. This close fit keeps out heat, cold, and water. Workers can pack things fast and safely. The material also blocks static and light for extra safety.

Tip: Good packaging helps stop damage and keeps products working right.

Aluminum foil laminated CPE helps both makers and buyers feel safe. Devices arrive ready to use, with no damage from temperature changes. This material helps deliver expensive electronics safely all over the world.

Plastic films like polyethylene or polypropylene are used for packaging. They help keep out dust and stop small scratches. But they do not block water, air, or light well. If electronics are wrapped only in plastic film, they can rust or fade. Plastic films do not handle heat or chemicals very well. They might tear or stretch when shipped. This can put devices in danger.

Aluminum Foil laminated CPE gives much better protection. The aluminum foil layer keeps out water, air, and light almost fully. The CPE layer makes the material strong and bendy. This mix keeps electronics safe when moving or stored. Makers pick this material for packaging that lasts and works well.

Note: For electronics that need the best safety, Aluminum Foil laminated CPE is better than regular plastic films in every way.

Paper packaging is light and easy to recycle. Many companies use it for simple things. But paper does not keep out water, air, or light. It soaks up water fast and can rip or break if pushed. Paper also does not stop static or electromagnetic waves. These problems make paper a bad pick for delicate electronics.

Aluminum Foil laminated CPE fixes these issues. The foil layer blocks water, air, and UV rays. The CPE layer keeps the package strong and bendy. Electronics stay dry, clean, and safe from harm. This material also stops holes and resists chemicals, which paper cannot do.

| Material Type | Moisture Barrier | Light Barrier | Puncture Resistance | Static Protection |

|---|---|---|---|---|

| Paper Packaging | Poor | Poor | Poor | Poor |

| Aluminum Foil laminated CPE | Excellent | Excellent | Excellent | Excellent |

Non-laminated films, like simple plastic or metalized films, give basic coverage. But they do not have the strong barrier of Aluminum Foil laminated CPE.

Aluminum Foil laminated films block water, air, and UV light very well. This is important for keeping electronics safe.

These films handle heat well, so they work for heat sealing and hot places.

Non-laminated or metalized films do not block as much. They may cost less or bend more, but they do not protect as well as Aluminum Foil laminated films.

Aluminum Foil laminated CPE has many layers. The outside layer gives strength and heat safety. The middle aluminum foil layer blocks gases, water, and light. The inside layer lets the package be sealed and adds support. Non-laminated films do not have this foil, so they protect less.

PE lamination in Aluminum Foil laminated films makes them harder to tear or poke.

These films also block grease, oils, and gases better than non-laminated ones.

They handle heat better, so they are safer for electronics that need sealing or face high heat.

Tip: When you need the most safety and trust, Aluminum Foil laminated CPE is the best pick for electronics packaging.

Aluminum foil laminated CPE is important for packaging electronics. Many companies use it to keep smartphones, tablets, and laptops safe. The film blocks water and air, so parts do not rust or break. Its anti-static layer helps stop static shocks that can hurt microchips. This keeps memory cards and other small parts safe.

Manufacturers like that this material is strong. It does not tear or get holes when shipped. The film can be printed on, so brands put logos or warnings right on the package. This makes it easy to know what is inside and helps with selling the product.

Keeps things like phones, tablets, and headphones safe

Protects chargers, cables, and batteries from water and static

Makes it easy to add labels and brand names to packages

Note: Many people want aluminum foil laminated CPE for electronics. Suppliers get big orders, which shows it is trusted and popular.

Industrial electronics need packaging that is very strong. Aluminum foil laminated CPE gives good protection in tough places. Factories and warehouses use it to wrap control panels and sensors. The film keeps out dust, oil, and chemicals that can break things.

Workers use heavy tools and machines. Packages might get dropped or hit. This material is tough and helps stop damage from bumps. It also bends, so it can wrap around many shapes and sizes.

A simple table shows how it is used in factories:

| Industrial Product | Packaging Benefit |

|---|---|

| Control panels | Moisture and dust barrier |

| Circuit boards | Static and impact protection |

| Sensors | Chemical resistance |

Tip: Using this packaging helps factories save money and time by stopping damage.

Medical devices need clean and safe packaging. Aluminum foil laminated CPE blocks germs, water, and light. Hospitals use it to pack tools, sensors, and monitors.

The anti-static layer keeps tiny circuits safe inside medical devices. The film does not let cleaning chemicals get in. It also bends, so it is easy to seal and keep things clean.

Keeps medical electronics dry and free from germs

Protects sensors and monitors from static and light

Helps keep devices safe in hospitals and clinics

Alert: Good packaging for medical electronics helps keep patients safe and makes sure devices work right.

Aluminum foil laminated CPE is good for the environment. Makers design it to cut down on waste and help recycling. The aluminum and CPE layers can be pulled apart at special recycling centers. Many places with good recycling systems take these materials.

This packaging helps electronics last longer. When devices last longer, fewer get thrown away. This means less trash goes to landfills. Companies also use less extra packaging because this material is strong. This cuts down on how much packaging gets wasted.

♻️ Note: Using packaging that can be recycled helps the planet and makes eco-friendly buyers happy.

Aluminum foil laminated CPE can be changed in many ways. Makers can make the packaging fit different electronics and brands. They can change the size, thickness, or color for each product. Printing can be done with digital or plate methods. Brands can put logos, instructions, or warnings right on the package.

The table below lists some common ways to customize:

| Customization Aspect | Options / Details |

|---|---|

| Printing Methods | Digital printing (detailed images), Plate printing (CMYK, cost-effective for wholesale) |

| Additional Laminate Layers | Nylon (tear strength), EVOH, PVDC, OPP, CPP, RCPP for heat resistance and strength |

| Sealing Features | Zipper, hang hole, tear notches, lip and seal |

| Material Structures | PET/AL/NYLON/PE, OPP/AL/PE (matte finish), PET/AL/CPP, PET/AL/RCPP, PET/AL/NYLON/RCPP |

| Appearance | Shiny or matte surface finishes |

Makers can pick different sealing styles, like envelope or flat. They can add things like oxidation resistance or static protection. These choices help keep things like circuit boards and USB drives safe. The many design options make sure each product gets the right protection.

Custom sizes and logo printing

Different material structures for special needs

High-frequency heat sealing for a tight seal

Tip: Custom packaging helps brands get noticed and keeps products safe.

Aluminum foil laminated CPE follows strict rules for safety and quality. Makers use quality systems and follow environmental rules when making it. The packaging meets world standards like ISO9001:2000, ISO14001:2004, and QS. These rules make sure every batch is safe and works well.

Testing uses GB and ASTM standards, which are known everywhere. The packaging also meets environmental rules in Europe and North America. Companies check every step to make sure the packaging is safe for electronics and the earth.

Alert: Picking packaging that meets world rules keeps products and the planet safe.

Aluminum foil laminated CPE gives great protection for electronics. It keeps out water, air, and light very well. The material does not tear or let in chemicals. It also stops static and blocks electromagnetic waves. This packaging is stronger than plastic or paper. It helps keep devices safe for a longer time. Manufacturers use it because it works well. People get products that last longer and stay safe.

️ To keep electronics safe and strong, manufacturers and buyers should pick aluminum foil laminated CPE.

Aluminum foil laminated CPE has a thin aluminum foil layer and CPE. This mix makes a strong and bendy barrier. It keeps electronics safe from water, air, light, and static.

The aluminum foil layer moves static charges away from parts. This helps stop static shocks that can break microchips and other pieces.

Many recycling centers can take this material. Special machines pull apart the aluminum and CPE. Recycling cuts down on trash and helps the environment.

Yes. This material follows strict safety and quality rules. It blocks water, air, and germs, so it works well for medical electronics.

Consumer electronics, control panels, and medical sensors all use it. The material keeps out water, static, and bumps during shipping and storage.

Yes. The CPE layer stands up to oils, acids, and many chemicals. This keeps electronics safe in tough places.

Manufacturers can pick different sizes, thicknesses, and printing. They can add zippers, tear notches, or special looks too.

Aluminum foil laminated CPE protects better from water, air, and light. It also blocks static and stops holes better than regular plastic film.