close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-17 Origin: Site

Ever wondered how products stay fresh and protected? Aluminum foil laminated film is the secret.This versatile material blocks moisture, oxygen, and light, keeping food, medicine, and industrial items safe.In this post, you’ll learn about its types, uses, and the high-quality solutions from Hangzhou VWIN.

Aluminum foil laminated films from Hangzhou VWIN are versatile materials used across multiple industries. They provide excellent protection against moisture, oxygen, and light while maintaining product integrity. These films are lightweight yet strong, offering thermal resistance, durability, and flexibility. They are widely used not only in packaging but also in industrial, medical, and electronic applications. With Hangzhou VWIN’s advanced manufacturing capabilities, these films can be customized to meet specific barrier, strength, and thermal requirements, making them ideal for both consumer products and high-performance industrial solutions.

Aluminum foil laminated films are widely used in food packaging for products such as snacks, dried goods, coffee, and seasonings. They create a reliable barrier that prevents moisture, oxygen, and light from spoiling the contents, which extends shelf life significantly. Hangzhou VWIN’s films feature multi-layer barrier designs and superior tear resistance, making them durable enough for automated packaging lines. Additionally, the films are printable, allowing high-quality branding or labeling. Their flexibility allows use in flexible pouches, stand-up bags, and sachets, ensuring products remain fresh and visually appealing while meeting industry standards.

| Product | Barrier Function | Typical Hangzhou VWIN Film |

|---|---|---|

| Snacks & Dry Goods | Moisture, Oxygen, Light | Aluminum-Plastic Multi-layer |

| Coffee & Seasonings | Aroma retention, Freshness | Aluminum-PET Laminates |

| Spices & Powdered Foods | Contaminant protection | Aluminum Multi-layer Films |

In pharmaceutical and medical industries, aluminum foil laminated films protect tablets, capsules, and medical devices from contamination and environmental factors. These films are essential for blister packs, sealing films, and other sensitive packaging. They prevent moisture and oxygen penetration, ensuring drugs maintain their potency and quality over time. Hangzhou VWIN’s films are heat-sealable and provide high-strength barriers, which make them compatible with automated production lines and complex packaging systems. Customizable layer structures allow additional features such as tamper-evident seals or anti-static properties, ensuring both product safety and regulatory compliance for pharmaceutical applications.

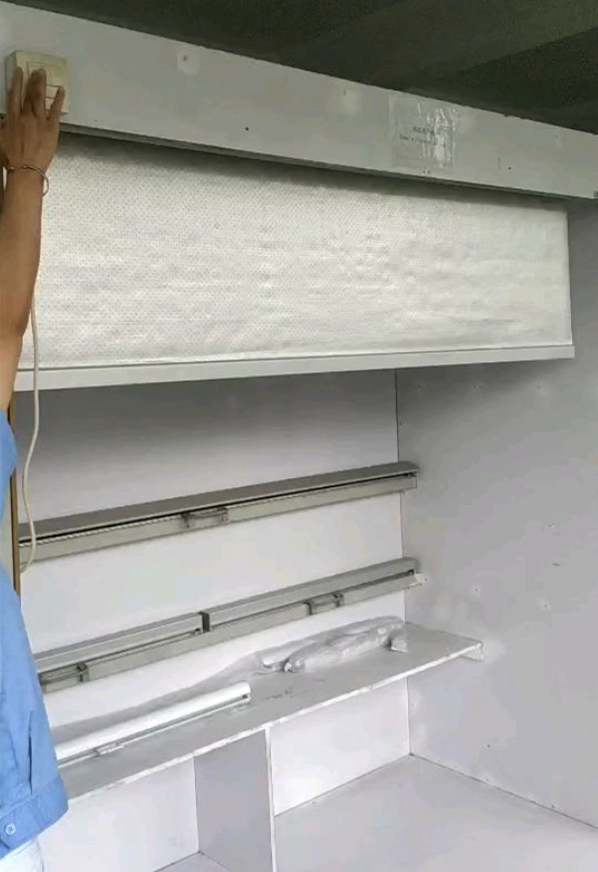

Hangzhou VWIN aluminum foil laminated films serve critical functions in industrial and construction sectors. They are used in HVAC ducting, building insulation, thermal management systems, and protective coverings for industrial equipment. These films provide excellent heat reflection, reduce energy loss, and offer lightweight insulation that is easy to handle and install. Aluminum-bubble laminated films are particularly effective, combining compressive strength, cushioning properties, and moisture resistance. Their flexibility and durability make them suitable for large-scale installation while maintaining high thermal performance. They also support multi-layer structures for additional strength or specialized industrial coatings, increasing system efficiency and safety.

| Application | Key Function | Recommended Film Type |

|---|---|---|

| HVAC Ducts | Thermal reflection, moisture resistance | Aluminum-Bubble Laminates |

| Building Insulation | Heat barrier, energy saving | Multi-layer Custom Films |

| Industrial Cushioning | Shock absorption, durability | PE Foam Laminates |

| Pipe Wrapping | Corrosion protection, thermal control | Aluminum-Bubble Laminates |

Aluminum foil laminated films play a vital role in electronics and EMI shielding applications. They are used to create anti-static packaging, conductive layers, and flexible protective films for electronic components. These films block electromagnetic interference and provide temperature resistance to protect sensitive devices. Hangzhou VWIN produces multi-layer laminated films that can integrate conductive, anti-static, and insulating layers in a single structure. This allows customized performance based on specific electronic requirements. They are suitable for packaging semiconductors, printed circuit boards, and flexible displays, ensuring both product safety and functional reliability during shipping, storage, and assembly processes.

In personal care and cosmetics, aluminum foil laminated films are widely used for face masks, creams, travel-size products, and sample packs. These films create a barrier against air, moisture, and contaminants, preserving product quality and extending shelf life. Hangzhou VWIN’s films are highly printable, allowing for premium brand packaging with vibrant colors and sharp graphics. They are also flexible and durable, suitable for pouches, sachets, and multi-layer packaging structures. Customizable laminates can include heat-seal layers or tamper-evident features, enhancing functionality. These films balance aesthetics and protection, ensuring cosmetic products maintain their appearance, freshness, and safety until use.

| Cosmetic Product | Barrier Function | Recommended Film |

|---|---|---|

| Face Masks | Air & Moisture barrier | Aluminum-PET Laminates |

| Travel Creams | Contaminant protection | Aluminum Multi-layer Films |

| Sample Packs | Lightweight, durable | Aluminum-Plastic Laminates |

| Sheet Masks | Aroma & active ingredient retention | Aluminum-BOPP Laminates |

Aluminum foil laminated films from Hangzhou VWIN are designed for performance. They combine aluminum’s natural barrier with other functional materials. Each combination targets specific uses, from food packaging to industrial insulation. You can choose flexible, durable, or highly reflective layers depending on your project.

Hangzhou VWIN offers a variety of material combinations for different needs:

Aluminum-Plastic Laminates: Aluminum + PET, BOPP, or PE film. Great for flexible packaging and heat-sealable products. It provides high barrier properties and good printability.

Aluminum-Paper Laminates: Aluminum + Kraft or Whiteboard paper. Strong, eco-friendly, ideal for snack bags and premium packaging.

Aluminum-Bubble Laminates: Aluminum + PE or XPE foam. Lightweight, thermal insulation, protective cushioning. Perfect for HVAC, construction, or cold chain transport.

Aluminum-Fabric Laminates: Aluminum + Glass fiber or industrial woven fabric. High tensile strength, heat resistance, and durability. Useful for industrial insulation and protective layers.

Multi-Layer Custom Structures: Supports three layers or more. Combines multiple materials to achieve barrier, thermal, or reflective requirements.

| Combination | Materials | Key Benefits | Typical Uses |

|---|---|---|---|

| Aluminum-Plastic | Aluminum + PET/BOPP/PE | High barrier, heat-sealable, printable | Food & pharma packaging |

| Aluminum-Paper | Aluminum + Kraft/Whiteboard | Strong, eco-friendly, printable | Snacks, premium bags |

| Aluminum-Bubble | Aluminum + PE/XPE foam | Insulation, cushioning, lightweight | HVAC, cold chain, construction |

| Aluminum-Fabric | Aluminum + Glass fiber/industrial cloth | Tear-resistant, heat-resistant, reflective | Industrial insulation, protective layers |

| Multi-Layer Custom | Aluminum + PET + foam/paper/fabric | Multi-functional, flexible, customizable | Advanced packaging & industrial solutions |

Hangzhou VWIN ensures precise specifications to match each project:

Aluminum foil thickness: 6μm – 50μm, adjustable depending on strength needed.

Total laminate thickness: 0.05mm – 2.0mm, supports light or heavy-duty applications.

Maximum width: 1500mm, can be slit, die-cut, or delivered as rolls or sheets.

Surface finishes: Mirror, matte, anodized, electrophoresis, printed, pre-treated adhesive layers.

These specifications make it easy to integrate Hangzhou VWIN films into complex packaging, insulation, or industrial systems. Each layer is engineered to adhere well, resist punctures, and maintain performance across different environments.

Hangzhou VWIN aluminum foil laminated films combine high performance, durability, and versatility. They protect products from environmental damage, maintain quality, and offer flexibility in packaging design. These films are used in food, pharmaceutical, industrial, and personal care packaging. Companies benefit from customizable structures that support brand visibility while ensuring product safety and longevity. Hangzhou VWIN focuses on premium material quality and precise manufacturing, giving their laminated films an edge over standard alternatives.

VWIN films provide outstanding protection against moisture, oxygen, light, and contamination. This makes them ideal for perishable food, pharmaceuticals, and industrial materials. They maintain product freshness, prevent spoilage, and extend shelf life even under challenging storage conditions. Their multi-layer construction ensures consistent barrier performance while supporting high-speed processing. Businesses can rely on these films to safeguard sensitive products from external influences.

Barrier Features Table:

| Application | Barrier Function | Typical Film Type |

|---|---|---|

| Food | Moisture & Oxygen | Aluminum-PET / BOPP |

| Pharmaceuticals | Contamination & Oxygen | Aluminum Blister Foil |

| Industrial | Light & Moisture | Aluminum Bubble Laminates |

| Electronics | Static & Humidity | Aluminum-PET Multi-layer |

Hangzhou VWIN laminated films are designed to resist tears, punctures, and abrasions. They remain intact during transport, handling, and high-speed packaging processes. The combination of aluminum with PET, PE foam, or industrial fabric increases mechanical strength without adding excessive weight. This durability reduces product loss and packaging waste. Customers can trust that even fragile or high-value items will stay protected. Reinforced laminates maintain performance under repeated stress, making them suitable for both consumer and industrial use.

These films easily adapt to various heat-sealing applications, including pouches, sachets, blister packs, and industrial wraps. They flex without cracking, allowing smooth forming, folding, and sealing. Reliable sealing minimizes leaks and ensures product integrity. Hangzhou VWIN films maintain barrier properties even after heat sealing, making them ideal for delicate or perishable goods. Their flexibility simplifies automated packaging operations and supports complex designs without compromising performance.

VWIN films offer excellent surface adhesion for high-quality printing and labeling. Brands can display logos, instructions, or decorative graphics with sharp clarity. Both matte and glossy finishes are available, giving products a premium appearance. This combination of visual appeal and functional performance enhances marketing potential. Printed films maintain durability under stress and exposure, ensuring brand messages remain visible throughout the product lifecycle.

Printing Options Table:

| Surface Type | Printing Method | Example Application |

|---|---|---|

| Glossy | Flexo / Gravure | Snack packaging |

| Matte | UV / Offset | Cosmetic sachets |

| Pre-treated | Heat-transfer | Pharmaceutical blister foil |

Hangzhou VWIN can design multi-layer films for specialized applications. Layers can include anti-static, thermal insulation, moisture barriers, conductive coatings, or flame retardant films. These structures meet the requirements of electronics, industrial, pharmaceutical, and high-end food packaging. Custom laminates combine multiple functionalities, reducing the need for additional materials. This results in lighter, stronger, and more efficient packaging solutions tailored for specific industry needs.

| Feature | Function | Application Example |

|---|---|---|

| Anti-static | Prevents static damage | Electronics packaging |

| Thermal insulation | Reflects heat, saves energy | HVAC duct wraps |

| Multi-layer barrier | Protects from moisture & oxygen | Snack and coffee packs |

| Conductive layer | EMI shielding | Flexible circuit protection |

Choosing the right laminated aluminum foil depends on your product type, sensitivity, and required shelf life. Food, pharmaceuticals, and industrial goods have different barrier and mechanical needs. For example, snacks need high moisture and oxygen resistance, while electronics require anti-static properties. Consider environmental factors like humidity, light exposure, or high temperatures that might degrade the product or film. Hangzhou VWIN helps by providing sample testing, structure customization, and technical optimization to ensure the film matches your packaging needs perfectly.

When selecting a laminated foil, functionality matters as much as barrier performance. Heat-sealing compatibility ensures secure closure for pouches and blister packs. Self-adhesive backing or peelable layers add convenience for consumers. Anti-static or fire-retardant layers protect sensitive or industrial items. Hangzhou VWIN can integrate these features into multi-layer designs while maintaining strength, flexibility, and barrier efficiency.

Functional Feature Table:

| Feature | Purpose | Example Use |

|---|---|---|

| Heat Seal | Secure closure | Food pouches, blister packs |

| Self-adhesive | Easy application | Labels, resealable bags |

| Anti-static | Protect electronics | Circuit boards, EMI shielding |

| Fire-retardant | Safety in industrial use | HVAC duct wraps |

Composite laminated films can be challenging to recycle because multiple materials are fused. Most standard recycling streams cannot separate layers efficiently. Hangzhou VWIN explores eco-friendly solutions, including recyclable substrates and biodegradable coatings. They work on R&D to reduce environmental impact while maintaining performance. Best practices also include educating consumers, optimizing material usage, and innovating new designs for greener packaging solutions.

Use of mono-material combinations for easier recycling

Biodegradable polymer coatings to reduce landfill impact

Lifecycle analysis to optimize material selection and reduce waste

| Sustainability Focus | Action |

|---|---|

| Recyclable Layers | Aluminum + single polymer film |

| Biodegradable Coating | Reduce environmental footprint |

| Consumer Education | Promote responsible disposal |

The aluminum laminated film industry is evolving rapidly. Lightweight multi-layer films reduce material usage while maintaining strength. Smart packaging, integrating QR codes, NFC tags, or sensors, is gaining popularity for traceability and consumer engagement. High-performance applications in engineering, construction, and renewable energy are expanding. Hangzhou VWIN invests in innovative film structures and multi-functional laminates to address future market demands, combining durability, barrier performance, and advanced features.

Future Trends Table:

| Trend | Application | Hangzhou VWIN Approach |

|---|---|---|

| Lightweight films | Food, packaging | Layer optimization for strength |

| Smart packaging | QR/NFC traceability | Integrated multi-layer films |

| High-performance laminates | Industrial, construction | Custom thermal, barrier, and mechanical designs |

| Renewable energy solutions | Solar, EV battery | Multi-functional reflective & protective layers |

Aluminum Foil laminated Film offers outstanding barrier protection, keeping products safe from moisture, oxygen, light, and contamination. It is widely used in food packaging, pharmaceuticals, industrial applications, electronics, and personal care products. Hangzhou VWIN provides high-quality laminated films that combine durability, flexibility, and heat-seal compatibility. Their products are highly customizable, allowing multi-layer structures, surface treatments, and functional enhancements tailored to specific needs. Customers can also benefit from sample testing, technical guidance, and structure optimization to ensure the best performance. Hangzhou VWIN films not only protect products effectively but also support brand presentation with excellent printability, making them a reliable choice for diverse industries.

A: Aluminum Foil Laminated Film is used for food, pharmaceutical, industrial, electronics, and personal care packaging, offering barrier protection against moisture, oxygen, light, and contamination.

A: Hangzhou VWIN offers aluminum-plastic, aluminum-paper, aluminum-bubble, aluminum-fabric, and custom multi-layer laminated films.

A: They provide high barrier performance, durability, tear resistance, heat-seal compatibility, flexibility, printability, and customizable multi-functional layers.

A: Select based on product sensitivity, shelf life, packaging environment, and required functionalities like heat-seal, adhesive, anti-static, or flame resistance. Hangzhou VWIN supports testing, structure customization, and design optimization.

A: Composite films are challenging to recycle. Hangzhou VWIN explores recyclable and biodegradable coatings, focusing on material optimization, consumer education, and innovation.

A: Trends include lightweight composites, smart packaging with sensors or QR codes, and high-performance applications in industrial, construction, and new energy sectors. Hangzhou VWIN leads in innovative multi-layer solutions.