close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-12-30 Origin: Site

Have you ever wondered how reinforced aluminum can enhance safety and efficiency? This advanced material, known as Aluminum Metal Matrix Composites (AMMC), combines aluminum with various reinforcements. In this article, we’ll explore what reinforced aluminum is, how it’s made, and its applications, featuring insights from Hangzhou VWIN Technology Co., Ltd.

Reinforced aluminum plays a crucial role in modern manufacturing and construction. Its enhanced physical and mechanical properties make it a preferred choice across various industries. This material combines the lightweight nature of aluminum with the strength of reinforcements, resulting in a product that excels in both durability and performance.

Key Benefits of Reinforced Aluminum:

● Increased Strength: The addition of materials like silicon carbide or alumina significantly boosts the tensile strength of aluminum, allowing it to bear heavier loads.

● Improved Wear Resistance: Compared to traditional aluminum, reinforced variants can withstand higher friction, making them ideal for applications such as automotive parts and aerospace components.

● High-Temperature Performance: Unlike standard aluminum, which may lose structural integrity at elevated temperatures, reinforced aluminum maintains its strength, making it suitable for thermomechanical systems.

Property | Traditional Aluminum | Reinforced Aluminum |

Tensile Strength | Moderate | High |

Wear Resistance | Low | High |

Temperature Stability | Low | High |

As industries focus on sustainability, the demand for energy-saving and environmentally friendly materials has surged. Reinforced aluminum fits this trend perfectly. Its lightweight nature contributes to fuel efficiency in vehicles and aircraft, reducing overall energy consumption. Moreover, it’s recyclable, aligning with the principles of a circular economy.

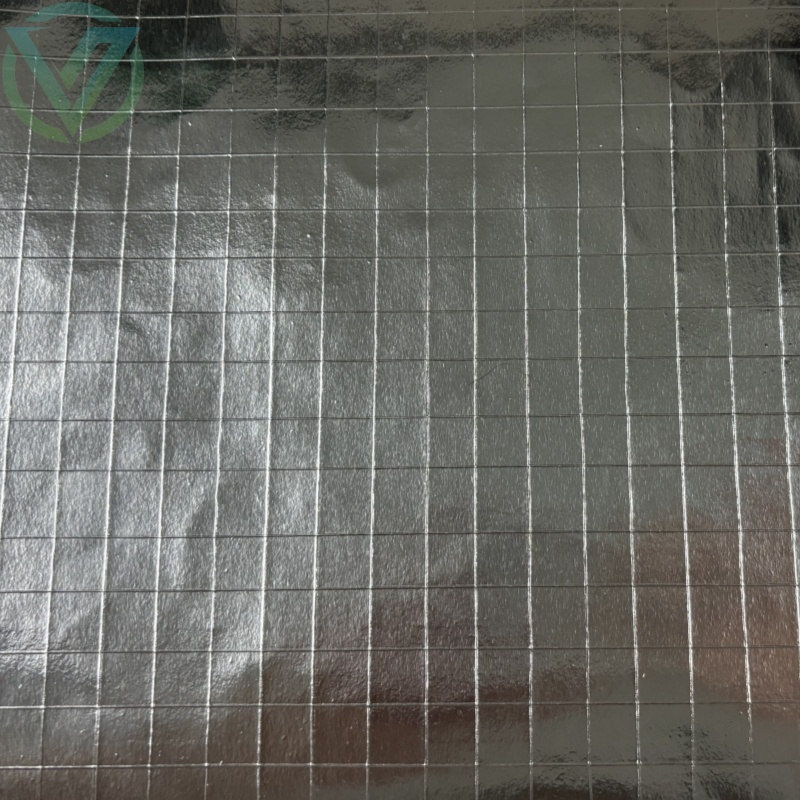

In sectors like construction and HVAC, reinforced aluminum is increasingly favored for insulation applications. Products like reinforced aluminum foil serve not only as thermal barriers but also as vapor barriers, preventing moisture penetration and enhancing energy efficiency in buildings.

This growing emphasis on sustainability means that companies are actively seeking materials that not only perform well but also minimize environmental impact. With reinforced aluminum, manufacturers can meet these demands while ensuring high performance and safety standards.

When comparing reinforced aluminum to traditional aluminum, the differences are striking. While standard aluminum is lightweight and corrosion-resistant, it lacks the strength needed for demanding applications. Reinforced aluminum addresses these limitations effectively.

In contrast to other materials like steel or titanium, reinforced aluminum offers a unique balance of weight, strength, and cost-effectiveness. For instance, in the aerospace industry, reinforced aluminum components are used to reduce the overall weight of aircraft, leading to significant fuel savings over time.

Overall, reinforced aluminum stands out as a versatile and essential material in today's manufacturing landscape, meeting the evolving needs of various industries while promoting sustainability and efficiency.

Reinforced aluminum significantly enhances fire safety, making it a crucial material in various applications. Its fire-resistant properties are achieved through the incorporation of specialized materials that withstand high temperatures and prevent flame spread. For instance, products like Reinforced Flame Retardant Aluminum Foil Scrim Kraft FSK Facing are designed specifically for this purpose.

These fire-resistant materials are vital in building decoration and equipment insulation. They not only protect structures from fire hazards but also contribute to overall safety standards in construction. In environments where fire safety is paramount, such as commercial buildings and industrial facilities, using reinforced aluminum can make a substantial difference.

Key Fire-Resistant Products:

● Reinforced Flame Retardant Aluminum Foil Scrim Kraft FSK Facing

● Fire Proof FSK Facing Vapor Barrier

Product | Fire Resistance Level | Applications |

Reinforced Flame Retardant Foil | High | Building insulation, HVAC |

Fire Proof Vapor Barrier | Moderate | Cold chain logistics, refrigeration |

Thermal insulation is another core function of reinforced aluminum. This material excels in reducing heat transfer, which is essential for energy efficiency. The thermal insulation properties of reinforced aluminum make it ideal for various applications, including roofing and solar panels.

For example, Aluminum FSK Foil Scrim Kraft Paper is specifically designed for roof insulation, helping to maintain comfortable indoor temperatures while minimizing energy costs. Similarly, Reinforced Aluminum Foil Kraft Paper for Thermal Solar Panels enhances the efficiency of solar energy systems by preventing heat loss.

Applications of Thermal Insulation:

● Roofing: Keeps buildings cool in summer and warm in winter.

● Solar Panels: Increases energy efficiency by retaining heat.

A vapor barrier is a crucial component in preventing moisture penetration, and reinforced aluminum serves this function effectively. It acts as a barrier that stops water vapor from passing through, which is essential in HVAC systems, refrigeration, and cold chain logistics.

Reinforced aluminum products, like the Fire Proof FSK Facing Vapor Barrier, are specifically designed to protect structures and equipment from moisture-related damage. This is particularly important in environments where humidity control is critical, such as food storage and pharmaceutical manufacturing.

Importance of Vapor Barriers:

● Moisture Protection: Prevents mold growth and material degradation.

● Energy Efficiency: Helps maintain consistent temperature and humidity levels.

Reinforced aluminum also offers excellent soundproofing capabilities, making it suitable for both residential and industrial applications. Its density and composition help reduce noise transmission, providing a quieter environment.

For instance, the FSK Coated PE Foil Aluminum Foil Composite Material is specifically designed as a soundproof panel. It can be used in various settings, from home theaters to industrial facilities, where noise control is essential.

Applications of Soundproofing:

● Residential Settings: Ideal for home theaters and recording studios.

● Industrial Settings: Reduces noise in manufacturing plants and equipment rooms.

Application | Product Used | Sound Reduction Level |

Home Theaters | FSK Coated PE Foil Composite Material | High |

Industrial Plants | Reinforced Aluminum Soundproof Panels | Moderate |

Reinforced aluminum is known for its remarkable strength and stiffness. By incorporating various reinforcement materials, such as ceramics or fibers, the load-bearing capacity of aluminum is significantly enhanced. This improvement allows structures to support heavier weights without compromising integrity. For example, aluminum reinforced with silicon carbide can withstand greater forces, making it ideal for demanding applications.

Key Points:

● Higher Load Capacity: Reinforced aluminum can handle more weight compared to standard aluminum.

● Stiffer Structures: It provides better rigidity, which is crucial in applications like aircraft wings and automotive frames.

When it comes to wear resistance, reinforced aluminum outperforms traditional materials like steel and cast iron. The addition of hard reinforcements allows it to resist abrasion and surface degradation effectively. In environments where friction is a concern, such as in machinery and tooling, reinforced aluminum proves to be a reliable choice.

Comparison Table: Wear Resistance

Material | Wear Resistance Level | Typical Applications |

Steel | Moderate | General construction |

Cast Iron | Low | Heavy machinery |

Reinforced Aluminum | High | Aerospace components, tools |

Reinforced aluminum exhibits excellent performance characteristics at elevated temperatures. Unlike standard aluminum, which may lose strength when heated, reinforced variants maintain their structural integrity even in high-heat environments. This property is essential for applications in aerospace and automotive industries, where components can experience extreme temperatures.

● Applications: Engine parts, exhaust systems, and high-performance vehicles benefit from this high-temperature stability.

One of the standout features of reinforced aluminum is its low weight-to-strength ratio. This characteristic is particularly important in the aerospace and automotive industries, where reducing weight can lead to significant improvements in fuel efficiency. By using reinforced aluminum, manufacturers can create lighter components without sacrificing strength, leading to better overall performance.

Benefits for Fuel Efficiency:

● Aircraft: Lighter planes consume less fuel, enhancing range and reducing operational costs.

● Automobiles: Lightweight vehicles accelerate faster and have improved fuel economy.

Thermal stability is another critical advantage of reinforced aluminum, closely tied to its Coefficient of Thermal Expansion (CTE). The CTE measures how much a material expands or contracts with temperature changes. Reinforced aluminum has a lower CTE compared to traditional aluminum, meaning it maintains its dimensions better under varying temperatures.

Significance:

● Precision Engineering: This stability is vital in applications where tight tolerances are necessary, such as in aerospace and automotive manufacturing.

● Durability: It helps prevent warping or dimensional changes, ensuring reliability in performance.

In summary, reinforced aluminum offers a unique combination of strength, wear resistance, and thermal stability, making it a preferred material across various high-performance applications. Its lightweight nature further enhances its appeal, especially in industries focused on efficiency and sustainability.

Reinforced aluminum achieves its remarkable properties through various reinforcing materials. These reinforcements enhance strength, durability, and performance across multiple applications. Let’s explore some common types of reinforcements used in reinforced aluminum.

Ceramics are a popular choice for reinforcing aluminum due to their hardness and thermal stability. Two common ceramic materials used include:

● Silicon Carbide: Known for its exceptional strength and wear resistance, silicon carbide significantly improves the toughness of aluminum. It is often used in applications requiring high durability, such as aerospace components and cutting tools.

● Alumina: This ceramic material offers excellent thermal resistance and mechanical strength. It helps maintain the structural integrity of aluminum in high-temperature environments, making it ideal for automotive and industrial applications.

Fibers are another effective reinforcement option, providing lightweight strength and flexibility. The most commonly used fibers are:

● Carbon Fiber: Renowned for its high strength-to-weight ratio, carbon fiber enhances the mechanical properties of aluminum. It is widely used in high-performance applications, including sports equipment and aerospace structures.

● Glass Fiber: This material is less expensive than carbon fiber and offers good tensile strength. Glass fiber-reinforced aluminum is often found in construction and automotive applications, where cost-effectiveness is essential.

Reinforcement Type | Key Properties | Typical Applications |

Silicon Carbide | High strength, wear resistance | Aerospace, cutting tools |

Alumina | Thermal stability, mechanical strength | Automotive, industrial components |

Carbon Fiber | Lightweight, high strength | Aerospace, sports equipment |

Glass Fiber | Cost-effective, good tensile strength | Construction, automotive parts |

In addition to ceramics and fibers, various metals and alloys are used to reinforce aluminum. Some key examples include:

● Steel: Adding steel to aluminum enhances its overall strength, making it suitable for heavy-duty applications. This combination is often used in construction and structural components.

● Scandium: This rare metal significantly improves the strength and weldability of aluminum alloys. It is especially valuable in aerospace applications, where performance and safety are critical.

Interestingly, industrial waste materials are also being utilized as reinforcements in aluminum. Using by-products like fly ash and red mud not only helps improve the properties of aluminum but also promotes sustainability.

● Fly Ash: A by-product of coal combustion, fly ash can enhance the mechanical properties of aluminum while reducing environmental waste. Its use in reinforced aluminum contributes to a more sustainable manufacturing process.

● Red Mud: This waste material from aluminum production can be repurposed as a reinforcement, helping to lower costs and minimize environmental impact.

Incorporating recycled materials into reinforced aluminum offers significant environmental advantages. By using industrial waste and other recycled materials, manufacturers can reduce the need for new raw materials, thereby conserving natural resources. This practice not only lowers production costs but also minimizes energy consumption and greenhouse gas emissions.

Using recycled materials aligns with the principles of a circular economy, where waste is minimized, and resources are reused. As industries continue to focus on sustainability, the use of recycled materials in reinforced aluminum will likely grow, benefiting both the environment and the economy.

Reinforced aluminum plays a pivotal role in the aerospace industry, where strength and weight are critical. It is commonly used in fuselage panels and engine components, providing the necessary durability while keeping aircraft lightweight. For example, parts for the F-16 fighter jet and the Airbus A380 utilize reinforced aluminum to enhance performance and fuel efficiency.

Key Applications:

● Fuselage Panels: Reinforced aluminum panels help reduce overall aircraft weight while maintaining structural integrity.

● Engine Components: Parts such as turbine blades and casings benefit from the enhanced thermal and mechanical properties of reinforced aluminum.

Aerospace Application | Material Used | Benefits |

F-16 Fighter Jet | Reinforced Aluminum | Lightweight, high strength |

Airbus A380 | Aluminum-Lithium Alloys | Improved fuel efficiency |

In the automotive sector, reinforced aluminum is essential for manufacturing high-performance parts. Components like brake disks and engine blocks utilize this material to improve strength and reduce weight. A particular focus is on connecting rods and pistons for electric vehicles, where efficiency is crucial for extending range.

Highlighted Uses:

● Brake Disks: Reinforced aluminum brake disks provide superior performance under high-stress conditions, enhancing safety and reliability.

● Electric Vehicle Components: Lightweight connecting rods and pistons contribute to better energy efficiency, making electric vehicles more competitive.

Automotive Component | Material Characteristics | Impact on Performance |

Brake Disks | High strength, lightweight | Improved stopping power |

Electric Vehicle Pistons | Reinforced Aluminum | Enhanced efficiency |

The defense sector relies heavily on reinforced aluminum for its ballistic protection capabilities. This material is vital in the production of armored vehicles and missile fins, where strength and weight are critical for performance and safety.

Key Applications:

● Ballistic Protection: Reinforced aluminum is used in armor plating to protect personnel and equipment from ballistic threats.

● Missile Fins: The lightweight nature of reinforced aluminum allows for better maneuverability and control in missile systems.

Defense Application | Material Benefits | Typical Use |

Armored Vehicles | Strong, lightweight | Personnel transport |

Missile Fins | High strength-to-weight ratio | Enhanced flight stability |

Reinforced aluminum also finds its way into consumer goods, particularly in high-end bicycles and kitchenware. Its lightweight and durable properties make it an excellent choice for products that require both strength and aesthetics.

Examples in Consumer Products:

● High-End Bicycles: Reinforced aluminum frames provide cyclists with a lightweight yet strong option, enhancing performance and ride quality.

● Kitchenware: Products like sheet pans and cookware benefit from reinforced aluminum's ability to withstand high temperatures and resist warping.

Consumer Product | Material Advantages | Market Segment |

High-End Bicycles | Lightweight, durable | Sports and recreation |

Kitchenware | Heat resistance, easy to clean | Home and professional cooking |

In summary, reinforced aluminum serves a diverse range of applications across industries, from aerospace to consumer goods. Its unique properties make it a preferred material, contributing to advancements in performance, safety, and efficiency.

The future of reinforced aluminum is bright, driven by continuous innovations and advancements in manufacturing technologies. One of the most exciting developments is the integration of additive manufacturing, commonly known as 3D printing. This technology allows for the creation of complex shapes and structures that were previously difficult or impossible to achieve. By using reinforced aluminum in 3D printing, manufacturers can produce lightweight components with enhanced strength and precision.

Emerging Technologies:

● Nanotechnology: The incorporation of nanoscale materials can significantly improve the mechanical properties of reinforced aluminum, resulting in stronger and lighter products.

● Hybrid Materials: Combining reinforced aluminum with other advanced materials, such as carbon fiber or advanced composites, can lead to even greater performance enhancements.

Technology | Description | Benefits |

Additive Manufacturing | 3D printing of reinforced aluminum components | Customization, reduced waste |

Nanotechnology | Use of nanoscale materials for reinforcement | Enhanced strength and durability |

Hybrid Materials | Combining aluminum with other advanced materials | Superior performance characteristics |

As industries increasingly focus on sustainability, reinforced aluminum is positioned to play a significant role in promoting environmental responsibility. One of the key benefits of using reinforced aluminum is its recyclability. Unlike many other materials, aluminum can be recycled multiple times without losing its properties. This characteristic not only reduces waste but also conserves energy and resources.

Environmental Benefits:

● Reduced Carbon Footprint: The production of recycled aluminum consumes significantly less energy compared to primary aluminum, leading to lower greenhouse gas emissions.

● Resource Conservation: Using reinforced aluminum helps minimize the extraction of raw materials, promoting a more sustainable approach to manufacturing.

The Role of Reinforced Aluminum in Sustainability: Reinforced aluminum's lightweight nature contributes to energy efficiency in various sectors. In the automotive and aerospace industries, lighter materials lead to improved fuel efficiency, which is essential for reducing overall emissions. Additionally, the use of reinforced aluminum in construction can enhance building energy performance, further supporting sustainability goals.

Sustainability Aspect | Impact of Reinforced Aluminum |

Energy Efficiency | Lighter materials reduce fuel consumption |

Recycling Potential | High recyclability lowers environmental impact |

Resource Efficiency | Minimizes raw material extraction |

In conclusion, the future of reinforced aluminum is marked by exciting innovations and a strong commitment to sustainability. As technologies advance and environmental considerations take center stage, reinforced aluminum will continue to be a vital material across various industries, driving progress and promoting a greener future.

Reinforced aluminum offers exceptional strength, lightweight properties, and durability. It is used in various industries, including aerospace, automotive, and consumer goods. Key benefits include enhanced performance, sustainability, and recyclability.

Explore reinforced aluminum products to meet your specific needs. Manufacturers like Hangzhou VWIN Technology Co., Ltd. are committed to quality and customer-centric solutions. Discover how reinforced aluminum can benefit your projects today!

A: Reinforced aluminum has added materials, like ceramics or fibers, enhancing its strength and stiffness compared to regular aluminum.

A: Its lightweight nature reduces overall weight in vehicles and structures, leading to improved fuel efficiency and lower energy consumption.

A: Yes, reinforced aluminum is highly recyclable, maintaining its properties through multiple recycling processes.

A: The aerospace, automotive, defense, and consumer goods industries benefit significantly from reinforced aluminum's properties.

A: Look for certifications like ISO 9001 for quality management and ASTM standards for material specifications.