close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

Is Glass Fibre Cloth Aluminum Foil the ultimate heat-resistant solution? This composite material combines the strength of glass fibre cloth with the protective qualities of aluminum foil. In various industries, its applications range from construction to aerospace. In this post, you'll learn about its composition, benefits, and heat resistance properties, providing insights into its industrial significance.

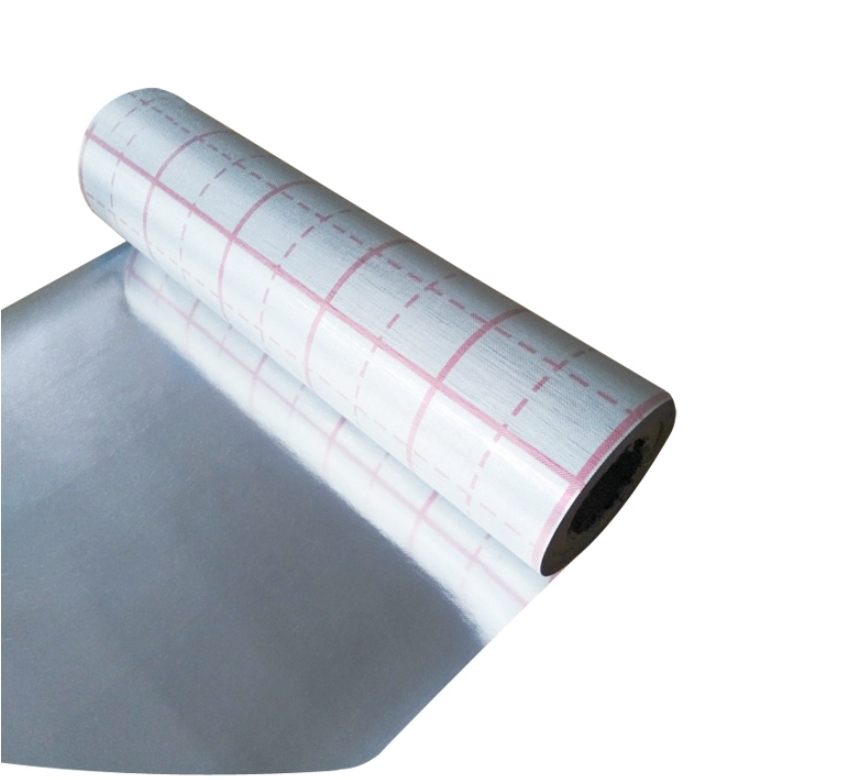

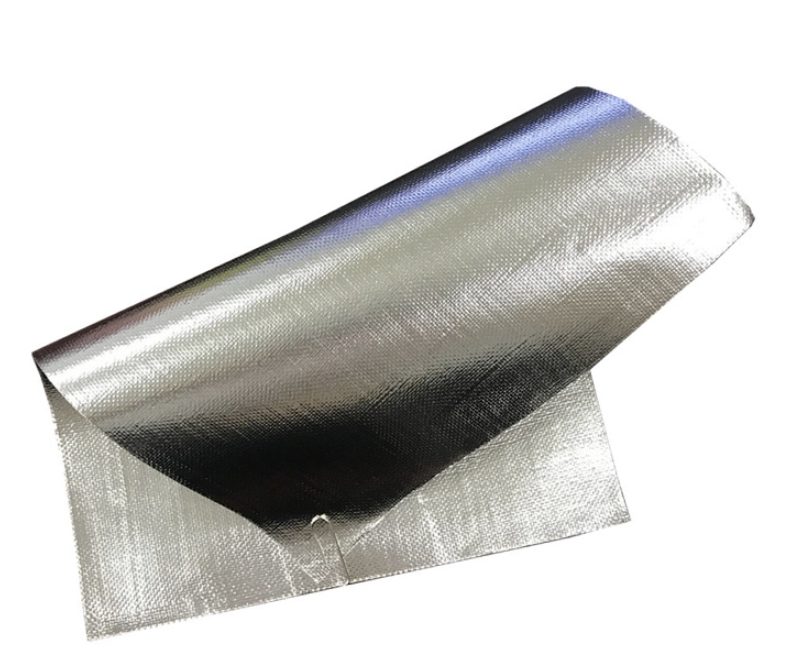

Glass fibre cloth aluminum foil is a composite material combining the strength and heat resistance of glass fibre cloth with the reflective and protective qualities of aluminum foil. This hybrid material is designed to offer superior performance in environments where both durability and thermal protection are essential. The glass fibre cloth provides a stable, heat-resistant base, while the aluminum foil layer reflects heat and protects against moisture, chemicals, and abrasion.

The material consists of two primary components:

● Glass Fibre Cloth: Made from woven strands of glass fibers, this cloth is known for its high tensile strength, flexibility, and resistance to heat and flames. The weave pattern can vary, but it generally forms a tight, durable fabric that withstands mechanical stress and thermal cycling.

● Aluminum Foil Layer: A thin sheet of aluminum is laminated onto one or both sides of the glass fibre cloth. This foil acts as a radiant heat barrier, reflecting infrared radiation and providing moisture and chemical resistance. The aluminum surface also helps prevent contamination and enhances the material's durability.

Together, these layers create a composite that balances mechanical strength, heat resistance, and protective qualities. The thickness and layering can be customized depending on the intended application.

The production of glass fibre cloth aluminum foil involves several key steps:

1. Weaving of Glass Fibre Cloth: Glass fibers are spun into yarns and woven into cloth using industrial looms. The weave type and density are controlled to meet specific strength and flexibility requirements.

2. Surface Treatment: The glass fibre cloth often undergoes surface treatments to improve adhesion and compatibility with the aluminum foil. This may include applying primers or coatings.

3. Lamination: Aluminum foil is laminated onto the treated glass fibre cloth using adhesives or heat bonding techniques. The lamination process ensures a strong bond without compromising the flexibility or heat resistance of the base fabric.

4. Finishing: The composite material is cut, inspected, and sometimes treated with additional coatings to enhance properties like flame retardancy or UV resistance.

5. Quality Control: Rigorous testing ensures the material meets specifications for strength, heat resistance, and durability.

This manufacturing approach results in a versatile material used in insulation, protective coverings, and heat shielding across industries.

Note: The quality of adhesion between glass fibre cloth and aluminum foil significantly affects the composite’s heat resistance and durability; therefore, proper surface treatment during manufacturing is critical for performance.

Glass fibre cloth aluminum foil achieves heat resistance through the unique combination of its components. The glass fibre cloth base withstands high temperatures due to its inherent thermal stability and flame resistance. It can endure prolonged exposure to heat without melting or degrading. The aluminum foil laminated on the surface acts as a radiant barrier, reflecting heat away from the material. This reflective property reduces heat absorption, preventing the underlying cloth from reaching critical temperatures. Together, they form a composite that resists heat conduction and thermal radiation effectively.

Compared to other heat-resistant materials, glass fibre cloth aluminum foil offers a balanced combination of flexibility, durability, and thermal protection. For example:

● Pure Aluminum Foil: Reflects heat well but lacks mechanical strength and tears easily.

● Glass Fibre Cloth Alone: Strong and heat-resistant but does not reflect radiant heat, allowing more heat transfer.

● Ceramic or Mineral Wool Insulation: Excellent heat resistance but bulky and less flexible.

Glass fibre cloth aluminum foil stands out by providing both mechanical strength and radiant heat reflection in a lightweight, flexible form. This makes it ideal for applications requiring both durability and thermal protection.

Several factors influence the heat resistance of this composite:

● Thickness of Layers: Thicker glass fibre cloth or aluminum foil layers increase thermal resistance but may reduce flexibility.

● Quality of Lamination: Strong adhesion ensures no gaps where heat can penetrate, maintaining effective insulation.

● Surface Treatment: Coatings on aluminum foil can enhance reflectivity and protect against oxidation, preserving heat resistance over time.

● Environmental Conditions: Exposure to moisture, chemicals, or UV radiation can degrade components, reducing heat resistance.

● Temperature Range: While the material withstands high heat, extreme temperatures beyond design limits can cause damage.

Understanding and controlling these factors during manufacturing and application ensures optimal heat resistance performance.

Note: Proper lamination quality and surface treatment are critical to maintain the heat resistance and durability of glass fibre cloth aluminum foil in demanding environments.

Glass fibre cloth aluminum foil is widely used in construction for insulation and protective barriers. Its heat resistance helps maintain temperature stability inside buildings by reflecting radiant heat and preventing heat transfer. The aluminum foil layer acts as a vapor barrier, reducing moisture intrusion that can damage insulation materials. This composite is often applied in roofing, wall insulation, and HVAC duct wrapping. It enhances energy efficiency by minimizing heat loss in winter and heat gain in summer, lowering heating and cooling costs. Its durability and resistance to environmental factors make it suitable for long-term use in harsh conditions.

In automotive and aerospace industries, this material serves as a thermal and acoustic insulator. It protects sensitive components from engine heat and external temperature extremes. The glass fibre cloth provides mechanical strength to withstand vibrations and mechanical stress, while the aluminum foil reflects radiant heat away from critical parts. It is used in engine compartments, exhaust systems, and heat shields. The lightweight nature of the composite helps reduce overall vehicle weight, improving fuel efficiency. Its flame resistance also adds a safety layer, crucial in aerospace applications where fire hazards must be minimized.

Glass fibre cloth aluminum foil plays a key role in electronics and electrical sectors by providing insulation and shielding. It protects devices from heat generated during operation, which can degrade performance or cause failure. The aluminum foil layer acts as an electromagnetic interference (EMI) shield, preventing signal disruption in sensitive electronic circuits. It is commonly used in cable insulation, circuit board protection, and heat shields for transformers and electrical enclosures. The material’s flexibility allows it to be shaped and fitted into compact spaces, essential in modern electronic designs.

Tip: When selecting glass fibre cloth aluminum foil for industrial use, consider the specific temperature range and environmental conditions to ensure optimal performance and durability.

Glass fibre cloth aluminum foil stands out for its exceptional durability. The glass fibre cloth base resists wear, tear, and mechanical stress, making it ideal for long-term applications. The aluminum foil layer adds protection against moisture, chemicals, and abrasion, which helps prevent corrosion and damage. Together, they create a composite that can withstand harsh environments and repeated thermal cycling without losing integrity. This durability reduces the need for frequent replacements, saving time and money over the product’s lifespan.

One of the main benefits of this composite is its ability to improve energy efficiency. The aluminum foil reflects radiant heat, reducing heat transfer through surfaces it covers. This reflective barrier helps maintain stable temperatures inside buildings, vehicles, or equipment, lowering heating and cooling demands. By minimizing heat loss or gain, it reduces the load on HVAC systems and engines, leading to significant energy savings. Over time, these savings translate into lower operational costs and a quicker return on investment for users.

Using glass fibre cloth aluminum foil can also benefit the environment. Its durability means fewer replacements, reducing waste. The energy savings achieved help lower carbon footprints by cutting down electricity or fuel consumption. Additionally, the materials used are often recyclable, supporting sustainable practices. When industries adopt this composite, they contribute to energy conservation and reduced greenhouse gas emissions, aligning with global environmental goals.

Tip: To maximize durability and energy savings, ensure proper installation and avoid exposure to harsh chemicals that can degrade the aluminum foil layer.

Despite its many advantages, glass fibre cloth aluminum foil has some limitations. One is its sensitivity to mechanical damage; sharp impacts or punctures can compromise the aluminum foil layer, reducing heat resistance and protective qualities. The material also has a maximum temperature threshold; exposure beyond this limit may cause degradation of the adhesive bond or slight weakening of the glass fibre cloth. Furthermore, prolonged exposure to harsh chemicals or UV radiation can deteriorate the aluminum foil's reflective properties, affecting thermal performance. It is important to select the right grade and thickness for specific environments to mitigate these risks.

Proper installation is crucial for maximizing performance and longevity. The material must be applied on clean, dry surfaces to ensure strong adhesion and avoid air gaps that reduce heat resistance. Skilled handling is necessary to prevent tears or wrinkles during installation, which can create weak points. Maintenance involves regular inspections to detect any damage or delamination early. Cleaning should be done with non-abrasive methods to preserve the aluminum foil's reflective surface. In industrial settings, protective coatings may be reapplied periodically to guard against environmental wear.

Glass fibre cloth aluminum foil tends to have a higher upfront cost compared to simpler insulation materials like foam or mineral wool. However, its durability and multi-functional properties often justify the investment. The material reduces energy costs by improving thermal insulation and reflecting heat efficiently, leading to long-term savings. Lower maintenance and replacement frequency also contribute to cost-effectiveness. When compared to high-performance ceramics or specialized heat shields, it offers a more flexible and lightweight alternative. Decision-makers should consider total cost of ownership, including installation, maintenance, and energy savings, to evaluate value accurately.

Tip: To enhance durability and heat resistance, ensure professional installation and routine maintenance of glass fibre cloth aluminum foil, especially in harsh or high-temperature environments.

Material technology for glass fibre cloth aluminum foil keeps evolving. New adhesives improve lamination strength, boosting heat resistance and durability. Innovations in aluminum foil coatings enhance reflectivity and corrosion resistance, extending material lifespan. Researchers explore nano-coatings to add self-cleaning and anti-oxidation features. Hybrid composites combining glass fibre with other high-performance fibers offer even better mechanical and thermal properties. These advancements allow manufacturers to produce lighter, stronger, and more heat-resistant composites tailored for specific industrial needs.

Emerging markets find new uses for glass fibre cloth aluminum foil. In renewable energy, it serves as insulation in solar panels and wind turbines, where temperature fluctuations are common. The growing electric vehicle sector uses it for battery thermal management, protecting cells from overheating. Smart building designs integrate this material in advanced insulation systems for energy-efficient homes. Medical devices benefit from its heat shielding and chemical resistance. As industries demand materials that combine flexibility, durability, and thermal protection, glass fibre cloth aluminum foil finds broader applications beyond traditional sectors.

Technological progress in manufacturing processes, like automated lamination and precision weaving, enhances product consistency and reduces costs. Digital simulation tools help engineers design composites that optimize heat resistance and mechanical strength for specific environments. These tools shorten development cycles and improve product performance. Additionally, sustainable production methods reduce environmental impact, aligning with global green initiatives. Integration with IoT sensors for real-time monitoring of thermal barriers is on the horizon, enabling predictive maintenance and smarter asset management. Such developments promise to increase the material’s value and adoption across industries.

Tip: Stay updated on material innovations and manufacturing technologies to select glass fibre cloth aluminum foil that meets future industry demands and sustainability goals.

Glass fibre cloth aluminum foil is heat-resistant, combining glass fibre's thermal stability and aluminum's reflective properties. It offers durability, energy efficiency, and environmental benefits, serving industries like construction, automotive, and electronics. Hangzhou VWIN Technology Co., Ltd. provides innovative solutions, ensuring high-quality adhesion and advanced material technology. Industry professionals should consider this versatile composite for enhanced thermal protection and durability in demanding applications.

A: Glass Fibre Cloth Aluminum Foil is a composite material combining glass fibre cloth with aluminum foil, designed for strength and heat resistance, ideal for thermal protection in various industries.

A: In construction, Glass Fibre Cloth Aluminum Foil is used for insulation and as a protective barrier, reflecting heat and preventing moisture intrusion to enhance energy efficiency.

A: Glass Fibre Cloth Aluminum Foil offers superior mechanical strength and radiant heat reflection compared to pure aluminum foil, making it more durable and effective in heat-resistant applications.

A: In automotive industries, Glass Fibre Cloth Aluminum Foil provides thermal and acoustic insulation, protecting components from heat while reducing vehicle weight for improved fuel efficiency.

A: Glass Fibre Cloth Aluminum Foil may have a higher upfront cost but offers long-term savings through durability, energy efficiency, and reduced maintenance needs compared to other insulation materials.