close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

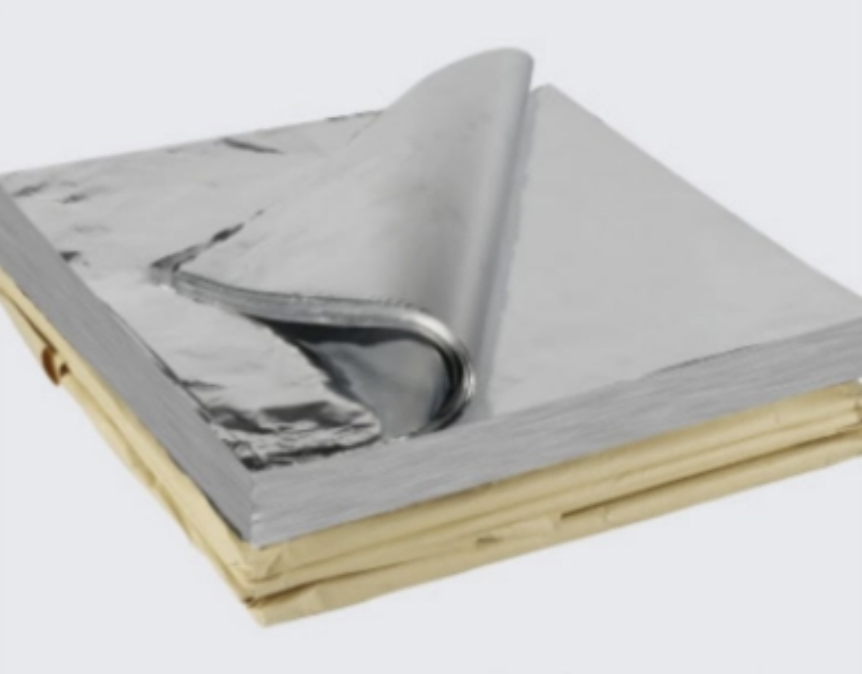

Ever wondered if aluminum foil laminated film is waterproof? This versatile material blends aluminum and plastic layers, offering durability and protection. It finds applications in food packaging, industrial settings, and consumer goods. In this post, you'll learn about its composition, waterproofing properties, and why it's essential for various uses."

Material | Water Resistance | Gas Barrier | Durability | Typical Use |

Aluminum Foil Laminated Film | Excellent | Excellent | High | Food, industrial packaging |

Pure Plastic Film (PE/PP) | Moderate | Low | Medium | Light packaging, disposable wraps |

Metalized Films | Good | Moderate | Medium | Snack packaging, decorative wraps |

Paper-Based Laminates | Low | Low | Low | Dry goods, short-term packaging |

Rubber/Silicone Coatings | High | Low | Medium | Waterproofing coatings, industrial use |

Aluminum foil laminated film combines multiple materials to create a composite that balances strength, flexibility, and barrier properties. The core material is a thin layer of aluminum foil, typically ranging from 6 to 20 microns thick. This metal layer is sandwiched between layers of plastic films such as polyethylene (PE), polypropylene (PP), or polyester (PET). Each plastic layer serves specific functions like heat sealing, mechanical strength, or printability.

The plastic films provide flexibility and protect the aluminum foil from damage, while the aluminum layer acts as a barrier to moisture, gases, and light. Adhesives or tie layers bond these materials together to ensure durability and prevent delamination.

The layering technique in laminated films is crucial for waterproofing performance. The aluminum foil layer forms a continuous, impermeable barrier that blocks water vapor and liquid water. Surrounding plastic layers add mechanical protection and prevent punctures or tears that could compromise waterproofing.

Proper lamination ensures no gaps or weak points exist between layers, eliminating pathways for water infiltration. The thickness and uniformity of the aluminum layer directly influence water resistance. Thicker aluminum foil generally offers better waterproofing but may reduce flexibility.

Additionally, the outermost plastic layer often has hydrophobic properties or coatings to repel water droplets, enhancing waterproof performance. The combination of these layers results in a film that prevents moisture penetration while maintaining flexibility and strength.

Aluminum's role in waterproofing is central. As a metal, it is inherently impermeable to water and water vapor. Its foil form creates a physical shield that stops moisture from passing through the film. This barrier protects the contents inside packaging or products wrapped with laminated film from humidity and water damage.

Besides waterproofing, aluminum foil also blocks oxygen, light, and odors, making it ideal for sensitive applications like food packaging. Its reflective surface can reduce heat transfer, which indirectly helps maintain product quality.

However, aluminum foil is thin and delicate, so it relies on the laminated plastic layers to provide mechanical strength and prevent punctures. If the aluminum layer is compromised, waterproofing effectiveness diminishes.

Tip: When selecting aluminum foil laminated films, prioritize those with high-quality lamination and thicker aluminum layers to ensure optimal waterproofing and durability for your applications.

Aluminum foil laminated film offers excellent waterproofing due to its unique multi-layer structure. The aluminum foil layer acts as a nearly impermeable barrier against water vapor and liquid water. This metal layer stops moisture from passing through the film, protecting the contents inside from dampness or water damage.

The plastic layers laminated on both sides protect the aluminum foil from punctures or tears. These layers also prevent direct contact with water, enhancing the film's resistance to water penetration. Additionally, some outer plastic layers may have hydrophobic coatings that repel water droplets, further improving waterproof performance.

Together, this combination creates a film that blocks water effectively while remaining flexible and durable enough for packaging or industrial use.

Compared to other waterproof materials, aluminum foil laminated film offers unique advantages:

● Versus Plastic Films Alone: Pure plastic films like polyethylene or polypropylene provide some water resistance but are more permeable to water vapor over time. Aluminum foil adds a metal barrier that drastically reduces permeability.

● Versus Metalized Films: Metalized films use a thin metal coating but are less robust than true aluminum foil layers. The foil provides better continuous coverage and stronger waterproofing.

● Versus Paper-Based Laminates: Paper laminates may resist water temporarily but degrade quickly when wet. Aluminum foil laminated films maintain integrity and waterproofing even under humid or wet conditions.

● Versus Rubber or Silicone Coatings: While rubber or silicone coatings offer waterproofing, they lack the barrier properties against gases and light that aluminum foil provides.

Thus, aluminum foil laminated film balances waterproofing, gas barrier, and mechanical strength better than many alternatives.

Despite its strengths, aluminum foil laminated film has some waterproofing limitations:

● Puncture Sensitivity: The thin aluminum layer can be punctured by sharp objects or rough handling. Once punctured, water can penetrate through the damaged area.

● Delamination Risk: Poor lamination quality or adhesive failure may cause layers to separate, creating gaps for water infiltration.

● Edge Sealing: If the film edges or seals are not properly finished, water may seep in through seams or overlaps.

● Chemical Exposure: Strong acids or bases can corrode aluminum, compromising the waterproof barrier.

● Flexibility Trade-Off: Thicker aluminum layers improve waterproofing but reduce flexibility, limiting some applications.

Therefore, high-quality manufacturing, careful handling, and proper sealing are essential to maintain effective waterproofing.

Tip: To ensure maximum waterproofing, choose aluminum foil laminated films with thicker foil layers and robust lamination adhesives, and inspect packaging seals regularly to prevent water ingress.

Aluminum foil laminated film is widely used in food packaging due to its excellent waterproofing properties. It prevents moisture from entering or escaping, which helps maintain food freshness and extends shelf life. For example, snack foods, coffee, and frozen meals often use this film to protect against humidity and contamination.

The film’s waterproof barrier keeps food dry and safe from spoilage caused by moisture. It also blocks oxygen and light, which can degrade food quality. This makes it ideal for packaging perishable and sensitive products.

In industrial settings, aluminum foil laminated film serves as a protective layer for various products. It shields items from water, chemicals, and environmental exposure. For example, in pharmaceuticals, the film protects medicines from moisture that could reduce effectiveness.

The film also finds use in electronics packaging, where it prevents moisture damage to sensitive components. Its waterproof nature helps maintain product integrity during storage and transportation.

Beyond food and industry, aluminum foil laminated film appears in many consumer goods. It is used in packaging for personal care products, such as cosmetics and hygiene items, where moisture resistance is vital.

Household items like detergents and cleaning products also benefit from waterproof packaging. The film ensures contents stay dry and uncontaminated, enhancing user experience.

Tip: For applications requiring reliable waterproofing, choose aluminum foil laminated films with robust lamination and consider the specific environmental conditions to maximize protection.

Aluminum foil laminated film is known for its impressive durability. The aluminum layer resists moisture, gases, and light, protecting contents from damage. The plastic layers surrounding the foil add strength and flexibility, preventing tears or punctures. This combination helps the film maintain its integrity over time, even in harsh conditions. Products wrapped in this film often enjoy longer shelf lives and better protection against physical damage.

The film also withstands temperature variations well. It does not easily degrade under heat or cold, which is crucial for food packaging and industrial uses. This longevity means less frequent replacement, reducing waste and saving costs.

Using aluminum foil laminated film can be cost-effective over the long term. Its protective qualities reduce product spoilage and damage, lowering losses. The film’s barrier properties mean less need for additional packaging materials or preservatives, further cutting expenses.

Manufacturers often find that the balance of durability and barrier performance justifies the initial investment. The film’s ability to extend product shelf life improves supply chain efficiency. This reduces returns and waste, ultimately saving money.

In many cases, the film’s lightweight nature also lowers shipping costs compared to heavier packaging options. This makes it an economical choice for bulk shipments or products requiring long-distance transport.

Aluminum foil laminated film raises environmental concerns but also offers sustainability benefits when managed properly. Aluminum is recyclable, and many recycling programs accept foil materials. Recycling aluminum saves significant energy compared to producing new aluminum, reducing carbon emissions.

However, the laminated nature of the film complicates recycling. Separating aluminum from plastic layers is challenging, so many recycling facilities cannot process these composites easily. Advances in recycling technology and design innovations aim to improve this.

Some manufacturers now produce films using recyclable or biodegradable plastics to enhance sustainability. Choosing films with eco-friendly certifications or made from recycled materials can reduce environmental impact.

Proper disposal and recycling education for consumers and businesses can help maximize the benefits of aluminum foil laminated films while minimizing waste.

Tip: For best value, select aluminum foil laminated films that balance durability and recyclability, and partner with recycling programs designed to handle laminated materials to support sustainability goals.

While aluminum foil laminated film offers excellent waterproofing and barrier properties, it comes with some drawbacks. The thin aluminum layer is prone to punctures and tears if handled roughly or exposed to sharp objects. Once damaged, the waterproof barrier is compromised, allowing moisture to penetrate.

The film can also be susceptible to delamination if adhesives fail or if layers separate under stress. This separation creates pathways for water infiltration, reducing effectiveness. Additionally, the film’s flexibility can be limited by thicker aluminum layers needed for better waterproofing, which may restrict certain packaging designs or applications.

Chemical exposure is another concern. Aluminum foil can corrode when in contact with strong acids or bases, weakening the waterproof barrier. In such environments, special coatings or alternative materials may be necessary.

Environmental impact is a significant consideration for aluminum foil laminated films. The composite nature of the film—combining aluminum and plastic layers—makes recycling difficult. Separating these materials requires specialized processes that many recycling facilities lack, leading to landfill disposal in many cases.

Though aluminum itself is highly recyclable and recycling saves energy, the presence of plastic layers complicates the process. This contributes to waste and environmental burden if not managed properly.

Moreover, the production of aluminum and plastics involves energy consumption and greenhouse gas emissions. Manufacturers and users should weigh these factors when choosing packaging materials.

Efforts are underway to develop more recyclable laminated films or use biodegradable plastics. Selecting films made with recycled content or from suppliers committed to sustainability can reduce environmental impact.

Several alternatives exist for applications requiring waterproof films, each with pros and cons:

● Pure Plastic Films: Materials like polyethylene or polypropylene offer water resistance and easier recycling but have higher water vapor permeability and weaker gas barriers.

● Metalized Films: These films have a thin metal coating rather than a foil layer. They provide some barrier properties but are less durable and waterproof than aluminum foil laminated films.

● Paper-Based Laminates: Often combined with coatings or plastic layers, these are more eco-friendly but less effective against moisture and may degrade quickly if wet.

● Biodegradable Films: Emerging options made from plant-based polymers offer environmental benefits but currently lack the barrier performance of aluminum foil laminates.

Choosing the right alternative depends on the specific waterproofing needs, environmental goals, cost considerations, and application requirements.

Tip: When selecting waterproof films, balance performance needs with environmental impact by considering recyclable or biodegradable alternatives and verifying the quality of lamination to avoid delamination and punctures.

The future of aluminum foil laminated film is bright, especially in waterproofing. Manufacturers are developing advanced lamination techniques that improve bonding between layers, reducing delamination risks. New adhesives with enhanced moisture resistance help maintain integrity even under harsh conditions.

Nanotechnology plays a growing role, adding ultra-thin coatings that repel water more effectively without adding bulk. These hydrophobic coatings prevent water droplets from sticking, boosting waterproof performance. Some innovations include self-healing layers that seal minor punctures automatically, extending film life and reliability.

Moreover, research focuses on flexible aluminum alloys or composite foils that offer better puncture resistance while retaining waterproof qualities. These advancements aim to solve the trade-off between thickness for waterproofing and flexibility for handling.

Demand for aluminum foil laminated film is rising globally, driven by industries needing reliable waterproof packaging. Food and beverage sectors continue to push growth due to strict hygiene and shelf-life standards. Pharmaceuticals and electronics packaging also increase usage, requiring moisture protection for sensitive products.

Sustainability trends influence market growth. Buyers seek films that combine waterproofing with eco-friendly features, such as recyclability or reduced plastic content. This demand encourages suppliers to innovate and offer greener options without compromising performance.

Analysts project steady growth in laminated film markets over the next 5-10 years. Emerging markets contribute significantly as packaging modernization spreads. The need for energy-efficient, durable, and waterproof packaging will fuel investment in new materials and production technologies.

As technology evolves, new applications for aluminum foil laminated film emerge. One area is flexible electronics packaging, where waterproof films protect delicate circuits from moisture without adding weight. Another is in agriculture, using laminated films for waterproof crop covers or seed packaging.

Medical devices and wearable sensors also benefit from waterproof films that shield components from sweat and environmental moisture. Even construction materials may adopt laminated films as waterproof barriers in specialized insulation or vapor retarders.

Additionally, energy-saving refrigeration covers made from woven aluminum fabrics show promise for commercial use, cutting energy costs and maintaining product quality during off-hours (example application). These night covers demonstrate how waterproof laminated materials can extend beyond traditional packaging.

Tip: Stay updated on new lamination adhesives and hydrophobic coatings to enhance waterproofing while meeting sustainability goals in your packaging solutions.

Aluminum foil laminated film offers excellent waterproofing capabilities due to its multi-layer structure, combining aluminum and plastic. The aluminum layer acts as a barrier to moisture, making it ideal for packaging needs. Despite some limitations, such as puncture sensitivity, the film remains a top choice for waterproof packaging. Hangzhou Hangzhou VWIN Technology Co., Ltd. provides high-quality aluminum foil laminated films, ensuring durability and protection. Their products deliver value by extending shelf life and reducing spoilage, proving beneficial for various industries.

A: Aluminum Foil laminated Film is waterproof due to its multi-layer structure, with an aluminum foil layer acting as a barrier against water vapor and liquid, supported by protective plastic layers.

A: Aluminum Foil laminated Film offers superior waterproofing, gas barrier, and mechanical strength compared to pure plastic films, metalized films, and paper-based laminates.

A: Its waterproof and barrier properties keep food fresh by blocking moisture, oxygen, and light, extending shelf life and maintaining quality.

A: The composite nature complicates recycling, but using recyclable materials and partnering with specialized programs can mitigate environmental impact.