close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-12-23 Origin: Site

Have you ever wondered how to keep your food fresh longer? Food preservation is crucial in today’s fast-paced world.

In this article, we explore the effectiveness of aluminum foil laminated film in preserving food.

You’ll learn about its unique properties and how it can extend the shelf life of various food items.

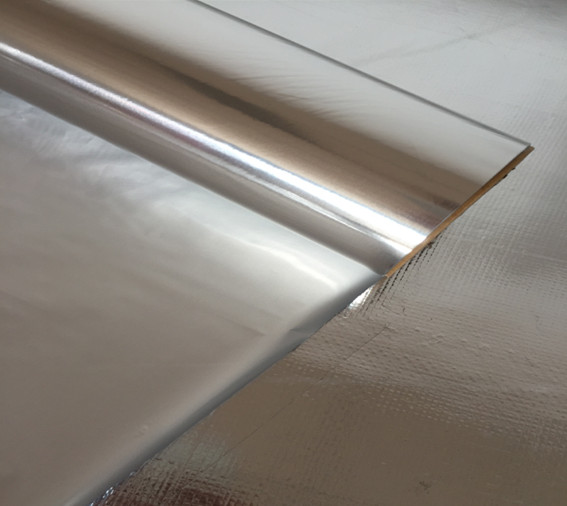

Aluminum foil laminated film is a versatile packaging material widely used in food preservation. It consists of multiple layers, primarily aluminum foil combined with other materials like PET (polyethylene terephthalate) or PE (polyethylene). This unique composition creates a high-barrier film that effectively protects food from external factors.

The film's structure typically includes:

● Aluminum Foil Layer: Provides an excellent barrier against light, oxygen, and moisture.

● PET/PE Layers: These layers add strength and flexibility, making the film suitable for various applications.

This combination results in a durable and effective packaging solution. The layering process enhances its barrier properties, ensuring food remains fresh for longer periods.

The production of aluminum foil laminated film involves a precise layering process. Here's a brief overview:

1. Layering: Aluminum foil is first combined with PET or PE. This is done through a lamination process, where heat and pressure bond the layers together.

2. Cooling: After lamination, the film is cooled to maintain its structure.

3. Cutting and Packaging: The film is then cut into desired sizes for various applications.

This method ensures that the film retains its protective qualities while being adaptable for different packaging needs.

Aluminum foil laminated film has numerous applications in food packaging, including:

● Food Packaging: Ideal for snacks, ready-to-eat meals, and frozen foods.

● Cold Chain Storage: Used in packaging that requires temperature control during transport.

● Medical and Pharmaceutical Packaging: Protects sensitive products from moisture and light.

Application | Benefits |

Food Packaging | Extends shelf life, maintains freshness |

Cold Chain Storage | Prevents thawing, ensures temperature stability |

Medical Packaging | Protects against contamination and degradation |

This film is essential in maintaining food quality and safety, making it a popular choice among manufacturers and consumers alike. Its adaptability and effectiveness in preserving food make it a valuable asset in the packaging industry.

Aluminum foil laminated film is a powerful tool for preserving food. It works through several key mechanisms that protect food from spoilage, ensuring that it stays fresh and safe for consumption. Let’s explore how this innovative film achieves its remarkable preservation capabilities.

One of the standout features of aluminum foil laminated film is its total barrier protection. The aluminum foil layer serves as a formidable shield against three major threats to food quality:

● Light: Ultraviolet (UV) and visible light can degrade food, causing nutrient loss and altering flavors. The foil effectively blocks this light.

● Oxygen: Oxygen exposure leads to oxidation, which can spoil food and diminish its taste. The film's barrier reduces oxygen infiltration.

● Moisture: Excess moisture can cause mold growth and spoilage. The film prevents moisture from entering or escaping the packaging.

These protective factors are crucial in maintaining the freshness of various food products. For instance, snacks and dried fruits remain crisp, while meats retain their flavor and texture.

Another critical function of aluminum foil laminated film is its ability to act as a contamination shield. This film prevents bacterial contamination in several ways:

● Barrier Against Microorganisms: The dense structure of the film inhibits bacteria and other pathogens from penetrating the packaging.

● Comparison with Other Materials: Unlike some plastic films, aluminum foil does not allow microbial growth. This makes it a superior choice for food safety.

Material Type | Barrier Properties | Contamination Prevention |

Aluminum Foil | Excellent barrier against light, oxygen, and moisture | High |

Plastic Films | Varies; often allows some gas exchange | Moderate |

Paper Packaging | Poor barrier; susceptible to moisture | Low |

This means that foods packaged in aluminum foil laminated film remain safe for longer periods, enhancing both quality and shelf life.

The film’s design also plays a vital role in aroma retention. Foods have unique scents that contribute to their overall appeal. Here’s how aluminum foil laminated film helps:

● Locking in Natural Aromas: The airtight seal created by the film prevents volatile compounds from escaping, which keeps the food smelling fresh.

● Odor Absorption Prevention: It also stops external odors from seeping in, ensuring that flavors remain intact.

For consumers, this means that meals retain their intended taste and aroma, enhancing the overall eating experience. Imagine opening a bag of chips and being greeted by that irresistible crunch and smell—this film makes it possible!

Aluminum foil laminated film is not only effective at preserving food but also offers impressive heat stability. This feature is particularly important for certain applications:

● Heat-Resistant Properties: The film can withstand high temperatures, making it suitable for processes like retort packaging, where food is cooked and sealed in the same package.

● Applications in Retort Pouches: This type of packaging is commonly used for ready-to-eat meals, soups, and sauces, allowing them to be stored without refrigeration.

The ability to endure heat while maintaining integrity ensures that food remains safe and delicious, even after extended storage.

Application Type | Description | Benefits |

Retort Pouches | Heat-treated packaging for meals | Long shelf life |

Microwaveable Films | Designed for reheating food | Convenient for consumers |

Oven Bags | Suitable for baking and roasting | Enhances flavors |

Aluminum foil laminated film is a versatile solution that effectively preserves food quality through its unique properties. Its barrier protection, contamination prevention, aroma retention, and heat stability make it an essential choice for food packaging today.

Aluminum foil laminated film plays a crucial role in various food preservation methods. Its unique properties make it ideal for different types of food packaging, ensuring that food remains fresh and safe. Let's explore some specific applications where this film shines in preserving food quality.

One of the most significant uses of aluminum foil laminated film is in cold chain food preservation. This film is essential for packaging frozen and refrigerated foods, helping maintain temperature stability during transport.

● Benefits: By providing an excellent barrier against moisture and oxygen, it prevents freezer burn and spoilage. This is particularly important for foods that require strict temperature control.

● Examples of Foods: Many products benefit from this type of preservation, including:

○ Fresh Meat: The film prevents oxidation and retains moisture, keeping meat juicy.

○ Seafood: It protects delicate flavors and textures, ensuring freshness.

○ Pre-Made Meals: Ready-to-eat meals packaged in aluminum foil laminated film stay safe and delicious during transport.

Food Type | Preservation Benefits |

Fresh Meat | Prevents oxidation; retains moisture |

Seafood | Maintains flavor and texture |

Pre-Made Meals | Ensures safety and taste |

Aluminum foil laminated film is also highly effective for preserving dry foods. Its properties help prevent moisture absorption and oxidation, which can spoil these items over time.

● Effectiveness: The film acts as a barrier against humidity, ensuring that dry foods remain crisp and flavorful.

● Detailed Examples: Several products benefit from this preservation method, such as:

○ Nuts: They stay crunchy and fresh, avoiding rancidity.

○ Biscuits: The film keeps them from becoming stale.

○ Milk Powder and Coffee: These products maintain their quality and aroma, making them appealing to consumers.

Another important application of aluminum foil laminated film is in the packaging of ready-to-eat meals. These meals often require vacuum packaging to ensure safety and quality.

● Role in Vacuum Packaging: The film inhibits microbial growth by creating an airtight seal, which is crucial for food safety.

● Maintaining Taste: By preventing odor diffusion and external contamination, it ensures that the flavors remain intact. This is particularly important for meals that are reheated before consumption.

Application Type | Key Benefits |

Vacuum Packaging | Inhibits microbial growth |

Ready Meals | Maintains taste and aroma |

Reheatable Packaging | Prevents odor diffusion and contamination |

Aluminum foil laminated film is a versatile solution that enhances food preservation across various applications. Its unique characteristics make it an essential component in the food packaging industry, ensuring that food remains fresh, safe, and delicious.

Aluminum foil laminated film is renowned for its exceptional performance in food preservation. Its unique structure provides multiple protective barriers that help maintain the quality and safety of food products. Let’s delve into the specific performance metrics that make this film an excellent choice for packaging.

One of the key features of aluminum foil laminated film is its ability to reduce oxygen levels effectively. Oxygen can lead to oxidation, which spoils food and diminishes its flavor. Here’s how the film works:

● Oxygen Reduction: The aluminum layer acts as a barrier, preventing oxygen from penetrating the packaging. This significantly slows down the oxidation process.

● Examples of Foods Benefiting: Several food items particularly benefit from this property, including:

○ Nuts: They are prone to rancidity when exposed to oxygen, but the film keeps them fresh.

○ Meats: The barrier helps maintain flavor and texture, ensuring that meats remain juicy.

Food Type | Benefit from Oxygen Barrier |

Nuts | Prevents rancidity |

Meats | Maintains flavor and texture |

Moisture control is critical in food preservation, and aluminum foil laminated film excels in this area. It provides an effective water vapor barrier, helping to keep food dry and safe.

● Importance of Moisture Control: Excess moisture can lead to spoilage, mold growth, and texture changes. The film prevents moisture from entering or escaping, ensuring food quality.

● Specific Food Types Requiring Protection: Certain foods are particularly sensitive to moisture, such as:

○ Dried Fruits: They can become sticky and lose their appeal if moisture infiltrates.

○ Powdered Foods: Items like milk powder or spices require a dry environment to maintain their quality.

Food Type | Moisture Sensitivity |

Dried Fruits | Can become sticky and spoil |

Powdered Foods | Requires dryness to avoid clumping |

Aluminum foil laminated film also serves as a light barrier, protecting food from light degradation. Light exposure can lead to nutrient loss and spoilage, particularly for sensitive products.

● Protection Against Light: The aluminum layer effectively blocks harmful UV and visible light, safeguarding the nutritional content of food.

● Nutritional Benefits for Light-Sensitive Foods: Foods that benefit from this protection include:

○ Fruits: Exposure to light can degrade vitamins and flavors.

○ Vegetables: Light can cause nutrient loss, making it essential to protect them during storage.

Food Type | Nutritional Benefits |

Fruits | Maintains vitamins and flavors |

Vegetables | Preserves nutrients |

Aluminum foil laminated film stands out due to its impressive performance metrics. Its ability to act as a barrier against oxygen, moisture, and light makes it an invaluable resource for preserving food quality and safety. This film not only enhances the shelf life of various products but also ensures they remain delicious and nutritious for consumers.

Aluminum foil laminated film offers numerous advantages in food preservation, making it a popular choice among manufacturers and consumers alike. Its unique properties and versatility contribute to its effectiveness in maintaining food quality. Let’s explore some key advantages of using this innovative packaging solution.

When it comes to aluminum foil laminated film, industry expertise plays a significant role in ensuring product quality. Many companies specialize in producing this type of film, leveraging their knowledge and experience to create high-performance packaging solutions.

● Overview of Specialized Companies: Leading manufacturers often have decades of experience in the field, focusing on research and development to enhance film properties. They understand the nuances of food preservation and can develop films that meet specific needs.

● Importance of Expertise: With a knowledgeable team, these companies can ensure that the film meets rigorous quality standards. Their expertise translates into products that effectively protect food from spoilage, ensuring safety and freshness.

Another significant advantage of aluminum foil laminated film is its customization and flexibility. Manufacturers often offer a range of options to cater to diverse food preservation needs.

● Options for ODM and OEM Services: Original Design Manufacturer (ODM) and Original Equipment Manufacturer (OEM) services allow businesses to create tailored solutions. This means that companies can work closely with manufacturers to develop films that meet their specific requirements.

● Tailoring Solutions: Whether it’s adjusting the thickness, barrier properties, or printing designs, customization ensures that the packaging aligns perfectly with the product it contains. This flexibility is crucial for brands looking to stand out in a competitive market.

Customization Type | Benefits |

Thickness Adjustments | Tailored barrier properties |

Custom Printing | Enhances brand visibility |

Specific Film Properties | Meets unique food preservation needs |

Quality assurance is paramount in food packaging, and aluminum foil laminated film adheres to stringent standards. Certifications play a vital role in ensuring product reliability and safety.

● Overview of Certifications: Many manufacturers obtain certifications such as ISO (International Organization for Standardization) and CE (Conformité Européenne). These certifications indicate compliance with international quality and safety standards.

● Importance of Quality Control Processes: Effective quality control processes are essential in maintaining high standards. These processes typically follow a sequence:

○ Incoming Quality Control (IQC): Ensures raw materials meet specifications.

○ Process Quality Control (PQC): Monitors production processes to maintain consistency.

○ Outgoing Quality Control (OQC): Final checks before products leave the facility.

Quality Control Process | Purpose |

IQC | Ensures materials meet specifications |

PQC | Maintains consistency during production |

OQC | Final checks for quality assurance |

The advantages of using aluminum foil laminated film extend beyond its protective qualities. With industry expertise, customization options, and rigorous quality assurance standards, this film stands out as a reliable choice for food preservation. Its ability to adapt to various needs makes it an invaluable asset in the packaging industry.

Aluminum foil laminated film is widely used in food packaging, yet several misconceptions persist regarding its safety and effectiveness. Addressing these myths is crucial to understanding the true benefits of this versatile material. Let’s clarify some common misunderstandings about aluminum foil and its interaction with food.

One prevalent myth is that aluminum foil can react negatively with food, particularly when it comes into direct contact. Many people believe that using aluminum foil can lead to harmful chemical reactions, but this is not entirely accurate.

● Understanding Interaction: In most cases, aluminum foil does not react with food unless subjected to extreme conditions. For typical storage and cooking scenarios, it remains stable and safe.

● Scientific Insights: Studies show that aluminum foil is generally inert under normal cooking and storage conditions. This means it doesn’t leach harmful substances into food, making it a safe choice for packaging.

Another misconception revolves around the safety of using aluminum foil for acidic or salty foods. Many worry that these types of foods may corrode the foil, leading to contamination.

● Acidic Foods: While acidic foods like tomatoes or citrus can interact with aluminum, the amount of aluminum that may leach into food is minimal and considered safe by health authorities.

● Salty Foods: Similarly, salty foods do not pose a significant risk when wrapped in aluminum foil. The film’s lamination helps create a barrier, minimizing any potential interaction.

Food Type | Interaction Risk | Safety Level |

Acidic Foods | Minimal leaching possible | Generally safe |

Salty Foods | Low risk of corrosion | Safe for short-term storage |

Lamination significantly enhances the performance of aluminum foil, particularly in preventing leaching. This process involves bonding layers of materials to create a protective barrier.

● Lamination Advantages: The laminated layer acts as a shield, reducing the likelihood of any aluminum leaching into food. This is especially beneficial for sensitive items, ensuring that they remain uncontaminated.

● Enhanced Food Safety: With lamination, the overall safety of aluminum foil laminated film is improved. It provides an extra layer of protection, making it a reliable option for various food types.

Finally, it’s essential to address the overall safety of using aluminum foil in food packaging. Regulatory agencies, including the FDA, have established guidelines for the safe use of aluminum in food contact applications.

● Regulatory Standards: Aluminum foil and laminated films must meet strict safety standards before being approved for food use. This ensures that they are safe for consumers.

● Consumer Confidence: Many studies support the safety of aluminum foil in food packaging, reinforcing its reputation as a reliable choice for preserving food quality.

Safety Aspect | Description |

Regulatory Approval | Must meet FDA and international standards |

Consumer Studies | Support safe use in food packaging |

By clarifying these common misconceptions, we can better appreciate the benefits of aluminum foil laminated film in food preservation. Understanding its safety and effectiveness helps consumers make informed decisions about their food packaging choices.

When discussing the preservation of food using aluminum foil laminated film, it’s essential to consider the environmental implications of this packaging material. From recycling practices to its impact compared to other materials, understanding these aspects helps consumers make informed choices.

Recycling is a crucial factor in assessing the environmental friendliness of any packaging material, including aluminum foil laminated film.

● Recyclability of Aluminum Foil: Aluminum itself is highly recyclable. Most recycling programs accept aluminum foil, and it can be recycled multiple times without losing quality. However, laminated films can pose challenges because they are often made from a combination of materials.

● Sustainable Practices: The push for sustainable practices in packaging is more important than ever. Companies are increasingly focusing on developing recyclable laminated films or those made from biodegradable materials. This shift not only helps reduce waste but also encourages a circular economy.

Material Type | Recyclability | Environmental Impact |

Aluminum Foil | Highly recyclable | Low impact when recycled |

Laminated Films | Varies; often not easily recyclable | Can contribute to landfill |

Biodegradable Options | Designed to break down naturally | Reduced long-term impact |

When evaluating aluminum foil laminated film, it’s helpful to compare its environmental impact with that of other common packaging materials like plastic and paper.

● Environmental Impact: Aluminum foil has a lower environmental footprint compared to many plastic films. While plastic can take hundreds of years to decompose, aluminum can be recycled indefinitely, significantly reducing waste.

● Benefits in Reducing Food Waste: One of the significant advantages of using aluminum foil laminated film is its effectiveness in preserving food. By extending the shelf life of products, it helps reduce food waste. Less food waste means fewer resources are wasted in the production process, contributing to a more sustainable food system.

Packaging Material | Decomposition Time | Recycling Potential | Impact on Food Waste |

Aluminum Foil | Indefinite (recyclable) | High | Reduces waste significantly |

Plastic | Hundreds of years | Low to moderate | Contributes to waste |

Paper | Months to years | Moderate | Less effective than foil |

Aluminum foil laminated film presents a compelling case for environmentally conscious consumers. Its recyclability, combined with its ability to reduce food waste, positions it as a responsible choice in food packaging. By understanding these environmental considerations, individuals and businesses can make better decisions that align with sustainability goals.

Aluminum foil laminated film is highly effective in preserving food quality. Its unique properties protect against oxygen, moisture, and light, ensuring freshness.

Consumers should consider this packaging option for its benefits.

Explore products that utilize aluminum foil laminated film to enhance your food preservation efforts and reduce waste.

A: Yes, aluminum foil is highly recyclable, but laminated films may vary in recyclability.

A: Acidic or salty foods can interact with aluminum, but minimal leaching occurs.

A: It has a lower environmental impact than plastic and helps reduce food waste.

A: Generally, aluminum foil is safe for food contact when used properly, with minimal health risks.

A: Look for certifications like ISO and CE, ensuring safety and quality standards are met.